How to Design Your Warehouse Layout for Maximum Efficiency

10 min

- Jana Gentry Smith

Managing a scaling ecommerce business with a chaotic warehouse is like coaching a football team with a scrambled playbook. Don't let your warehouse be the reason you're losing the game.

Instead, an organized warehouse is like having a well-structured game plan. Your team knows their positions, runs a smooth operation, and ships orders seamlessly. Is that your end goal?

If so, keep reading to learn about the perks of an efficient warehouse design and how to plan the perfect layout.

Reap the rewards of a well-designed warehouse layout

In football, an organized playbook improves team coordination, faster scoring, and reduced errors. Similarly, here is what a well-organized warehouse can help your business achieve:

Improved productivity: Quicker order processing, packing, restocking, and inventory management means more gets done in less time.

Fewer errors: Order accuracy results in cost savings and fewer returns.

Cost efficiency: Space-saving storage reduces labor costs and product storage issues.

Satisfied customers: Faster order processing and shipping promotes repeat business.

Safety: Clear aisles, organized storage, and well-maintained equipment keep warehouse staff safe, meaning fewer workers' compensation claims.

The right systems need to be in place to enjoy the benefits of efficient warehouse design. With that in mind, designing your warehouse involves careful planning, an effective inventory management system, and up-to-date technology.

4 questions to guide your warehouse layout design

Asking the right questions before creating your warehouse layout helps you tailor the plan to your business, optimizing space, ensuring safety, and ultimately scoring touchdowns in customer satisfaction. Consider these questions before you begin designing your warehouse:

Question 1: What are your space requirements?

Consider your rented or owned warehouse’s square footage and storage capacity so you can use space efficiently. Since your building’s size likely isn’t easily modified, you’ll want to know exactly how much space you have to work with.

Question 2: What are you shipping?

Along with the size of your warehouse, the variety and volume of your inventory affect your warehouse design.

First, determine the sizes of the products to be received and shipped. Knowing this will help you decide how to fit the inventory snugly and neatly on the shelves while leaving enough space for your team to move around easily.

Then, consider what types of products will be stored. Are they high-value? Perishable? Fragile? All of this plays into how to store and pick products safely.

Question 3: What needs to happen to keep your team safe and happy?

To keep your team safe, understand which guidelines apply to your warehouse layout to keep everyone safe.

These plans will likely include protocols for fire safety to keep everyone out of harm's way and designs for wider aisles so it’s easier for people to walk around without bumping into each other and getting hurt.

Beyond that, safety measures like clear signs, good lighting, and emergency exits can prevent accidents. Also, follow hazardous material storage guidelines and any industry-specific regulations that apply to your operations.

For more detailed guidance, check out OSHA's documentation on warehouse safety.

A healthy workplace also considers employees’ mental well-being. After all, a mess on the outside can cause a mess on the inside.

As a result, messy and disorganized workspaces can cause employees to feel unhappy and perform poorly. On the flip side, clean and organized work areas can boost performance and well-being.

Lastly, teaching your employees how to navigate and use the warehouse safely can mean the difference between life and death. Safety-informed workers will know how to stay safe and feel more confident and less likely to make mistakes that could lead to accidents.

Question 4: What technology tools streamline warehouse operations?

Finally, consider investing in time-saving software to help run your warehouse. Many large ecommerce companies use these tools to improve warehouse operations:

Enterprise Resource Planning (ERP) systems integrate back-office functions like inventory management, warehouse management, HR, and IT services into a unified platform. They give a comprehensive view of business operations and help streamline processes across the company.

Warehouse Management Software (WMS) like Veeqo focuses on managing and optimizing warehouse operations. Features include real-time insights, task coordination, and resource management that make the ecommerce warehouse environment easier to oversee. Some WMS's like Veeqo also include Inventory Management and shipping tools.

Inventory Management Software (IMS) helps businesses manage inventory efficiently. It tracks goods, monitors stock levels, and provides insights into supply chain performance. While it can be a component of an ERP system, it serves a more specialized purpose.

Now that you have answers to help guide your design, you can get down to the nitty-gritty of designing a detailed warehouse layout.

Use the Grid System as a framework for your warehouse design

Picture this: your warehouse, a beautifully organized grid, as clear as a football field. That's what you're aiming for. As players follow field routes, warehouse staff will navigate and handle inventory in designated zones.

To understand and plan the zones, draw a grid of your warehouse at scale. Then, divide the warehouse into the following zones within the grid:

Receiving zone

Stock doesn’t just magically appear on the shelves, so your team will need space to receive, unpack, put away, and book in new inventory as efficiently as possible.

The faster this happens, the sooner that stock is ready to sell. But, any errors or inefficiencies in the process will cascade through the entire supply chain.

To avoid this, include a dedicated receiving area in your design that consists of the following:

Dock-level equipment like conveyor systems and forklifts streamline the unloading to storage workflow.

Holding space to protect deliveries from damage until your team can process them.

Processing space to promptly add labels or barcodes to stock before storing the products in the warehouse instead of letting products build up.

Processing computer with warehouse management software so your team can record relevant details (like timestamps for receipt and storage) to refer to if any problems arise.

Inspection space to confirm delivery quantities are accurate and stock is free of damage in case of vendor, inbound shipping, or packaging problems.

To make your workspace even more user-friendly, consider displaying clear signage showing where to put incoming shipments so orders can be unloaded and sorted without bottlenecks.

Storage zone

Now, inventory that has been received and processed must stored. But where?

According to over 20 Veeqo retailers' records, 60% of a company’s sales come from just 20% of their products. To reduce picker walking time, identify that 20% of products from past sales data in your business, and then store these as close to the packing desk as possible so your team can retrieve and pack them quickly.

Also, keep inventory typically purchased together in the same zones to reduce travel time and design routes for staff to move efficiently around the warehouse.

Here are inventory management methods some companies use to store inventory:

ABC analysis classifies products based on demand patterns (A for high demand, B for medium, and C for low). Store A items where they’re easier to access than C items.

Selective racking stores high-demand items or items with varying sizes that need frequent retrieval on individual pallets.

Double-deep racking works best when products have higher inventory levels and slower turnover. It increases storage density by allowing pallets to be stacked two deep but requires specialized forklifts.

Drive-in and drive-through racking are ideal for stock with high turnover rates but a limited number of SKUs. Pallets are stored in deep lanes and accessible from both sides (drive-through) or one side (drive-in) to maximize usable space.

Push-back racking allows multiple pallets to be stored in a single lane. When one pallet is removed, those behind it move forward, ensuring FIFO (first in, first out) stock rotation.

Carton flow shelving works well with smaller items or slow-moving SKUs. It uses gravity to move cartons forward for easy picking.

Slotting and zoning assigns specific areas for certain product categories or sizes to make the most of space and reduce travel time during picking.

When designing the storage and picking zones of your warehouse layout, consider the specific products or items you ship most frequently and your most popular SKUs.

Then, store these items in easily accessible areas—closest to the office or shipping station—for quick and efficient order processing.

Picking Zone

Your picking zone's goal should be to reduce unnecessary movement and travel time for your pickers.

When arranging shelves, racks, and storage units, make aisles wide and products easy to find and pick when using digital picking software (or tools like the Veeqo scanner). Here are four setups many medium to large retailers use to boost picking efficiency:

Single order picking: Pickers collect one order at a time before moving on to the next.

Batch picking: Pickers collect 10-30 orders before returning to the packing desk.

Zone picking: Each picker only picks stock from their assigned area and passes it to the picker in the next zone.

Wave picking: All zones pick simultaneously and give their items to a packer who combines all the separate picks for each order.

Ultimately, determining which picking method works best for scaling your business can help you decide the size and shape of the space you need.

Packing and Shipping Zone

Once your pickers have gathered items for the order, aim to streamline the shipment process by creating a packing and shipping zone accommodating each workflow step.

Consider spaces and equipment, like the following, that are essential to punctual shipments:

Weigh station: Provide precise shipping costs by allocating space for scales.

Packing and shipping desk: Automate shipping label generation using a computer or tablet with WMS and printer to make the labeling process quicker and confirm accurate shipping information.

Packing materials and shipping equipment: Keep packing materials, boxes, tape, and labeling tools within easy reach of packers.

Quality control stations: Provide enough space to inspect packages for accuracy, quality, completeness, and damaged products to satisfy customer expectations.

Loading areas: Assign loading zones for carriers to reduce wait times so shipments can go out quickly.

If you have your packing and shipping zones sorted, consider finding the best WMS to automate and manage different aspects of your inventory and order processing. Doing so saves time and hassle while making your warehouse operations run more efficiently.

Label your aisles like Amazon

Amazon are known for being one of the most efficient order fulfillment operations in the world, right? Well you can organize your warehouse just like Amazon's, by following their super simple labelling system.

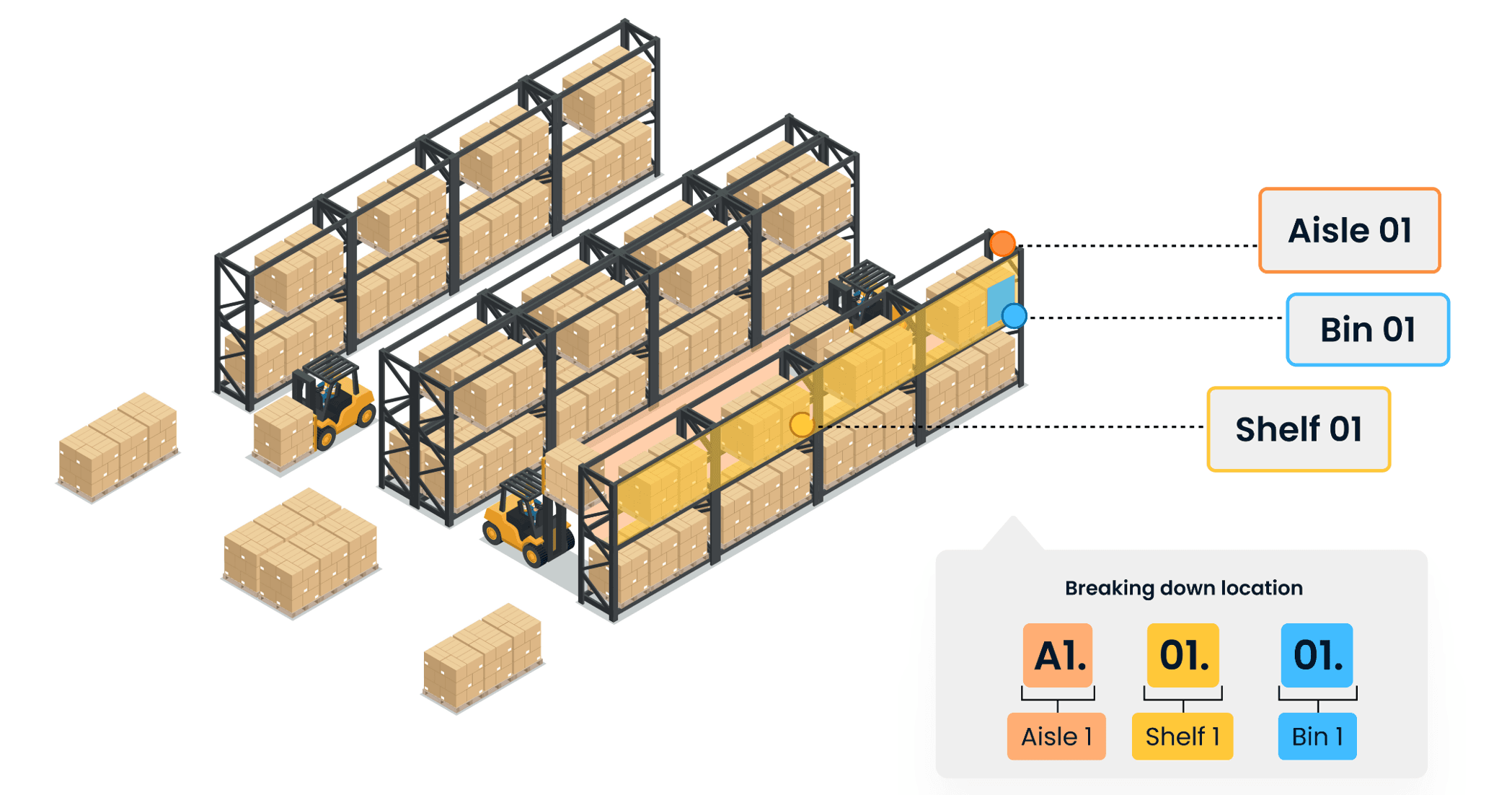

You see, they label their aisles and shelves alphanumerically - for instance, Aisle 1, Row 1, Shelf 1 becomes A1.01.01. This straightforward yet effective approach minimizes confusion and enhances efficiency, allowing you to sort your orders by location and make the best use of your warehouse space.

Stay organized with Warehouse Management Software (WMS)

Not only does the right WMS complement the packing and shipping zone, but it can also simplify operations in all other warehouse zones. Here’s how:

Receiving Zone: Track incoming shipments, verify inventory counts, and update the system with real-time information about newly received products.

Storage Zone: Select the best storage locations for products, organize product slotting, and maintain inventory accuracy by tracking items’ exact locations in the warehouse.

Picking Zone: Generate pick lists, refine pick paths, and guarantee pickers select the correct items with real-time updates on order status and inventory availability.

Packing and Shipping Zone: Generate shipping labels, confirm order accuracy, and track outgoing shipments by integrating with shipping carriers and automating shipping documentation.

Inventory Control and Monitoring: Track inventory levels, track product movements, and send alerts for low stock, overstock, or discrepancies.

While managing a busy warehouse can be chaotic and overwhelming, WMS can ease the disarray with streamlined processes, automated tasks, and real-time data insights, which reduces the risk of errors.

This means your warehouse will be productive and safe, making it easy for your team to do more in less time.

Tackle designing your warehouse layout with Veeqo

Think of your warehouse as a football team. Without a game plan, it's chaos.

But when you use the grid and labelling system to design your warehouse layout, and Veeqo's warehouse management software, you get that game plan—streamlined processes, real-time insights, and boosted productivity.

Ready to improve the efficiency of your warehouse’s design and workflow? Sign up for Veeqo or schedule a demo today.