What Is a SKU? How to Create SKU Numbers & Use Them Like A Pro

5 min

- Mike Glover

The humble SKU may seem like an innocuous little number. But it plays a huge role in effective inventory management.

Even the most seasoned ecommerce pros can be forgiven for not knowing too much about SKUs.

So the chances are, you fall into at least one of three categories:

- SKUs are there, but set up sub-optimally.

- SKUs are set up right, but you're not making full use of them.

- You're in SKU nirvana making full use of them.

This post covers everything you need to get into that third category - including how to create SKU numbers, and get the most out of them when it comes to tracking inventory, replenishing stock, and gaining sales insights.

Table of contents

- What is a SKU?

- SKU vs Barcode vs UPC

- How to create SKU numbers

- Aligning SKUs across your sales channels

- Merging products without updating SKUs

- Using SKUs to their full potential

What is a SKU?

A SKU (stock-keeping unit) is an alphanumeric code assigned to products and/or variants in a retailer's catalogue. Each SKU in an inventory should be unique, helping to identify, track and manage all the individual variants in question.

SKUs are also not universal – meaning they can be unique to your business, and tailored to what suits you best.

Good SKUs will therefore usually follow a standardised formula across the company. For example:

- VQO-TS-BL-SM: Stems from Veeqo - T-Shirt - Blue - Small.

- VQO-TS-BL-LG: Stems from Veeqo - T-Shirt - Blue - Large.

- VQO-TS-RD-LG: Stems from Veeqo - T-Shirt - Red - Large.

This formula can (in theory) be whatever you want. But there are some best practices to keep in mind, which we get into later in this post.

SKU vs Barcode vs UPC

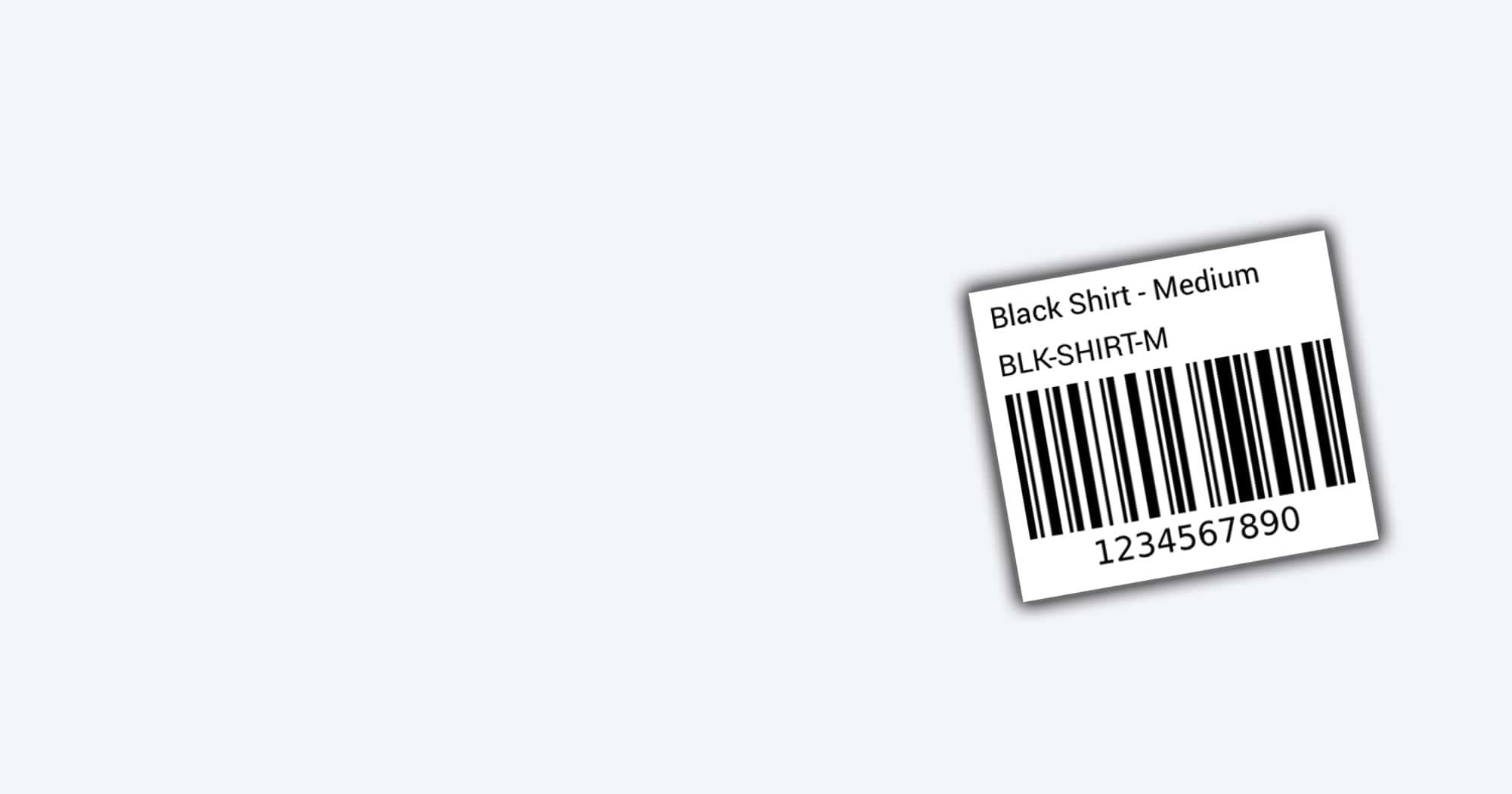

Before going any further, it's important to first clear up the difference between SKUs, barcodes and UPC numbers.

- Barcode. The series of thin black bars that barcode scanners use to digitally identify products in a company’s inventory.

- UPC (Universal Product Code). A 12-digit numerical code applied to a product by the Global Standards Organisation, which remains universally attached no matter where it’s sold.

- SKU. An alphanumeric code a business can assign each product variant in its inventory to help with internal tracking and identification.

How to create SKU numbers

Your SKUs should follow a logical architecture that's repeatable for any inventory variant. So it's important to decipher a clear SKU architecture, and stick with it.

Here's how to create SKU numbers along these lines:

1) Include only important information

Always remember that the goal is to help employees and delivery teams understand what product a SKU is referring to as quickly as possible.

So including relevant data (and omitting anything erroneous or obvious) makes for the best SKU architecture.

Do you stock hundreds of products but never anything outside of the Nike brand? Then including this in your SKU is pretty pointless. But it becomes extremely important if you sell items from Nike, Adidas, Reebok, etc.

Or if you sell to women only, adding an ‘F’ or ‘W’ in the SKU is pointless.

2) Commit to your format

Your format is completely up to you. But there are a few things to consider in your naming process:

- Keep the same order and format for each SKU.

- Try to limit to between eight and 12 characters.

- Always start with a letter, not a number.

- Go from broad to narrow – so NK-TS-GRN-SM, not SM-GRN-TS-NK for a small green Nike t-shirt. (Products should group together in a logical way when listing your SKUs alphabetically.

3) Be unique

At this point, you might be thinking something along the lines of:

"This is great... but I sell 17 different small blue t-shirts and this SKU example doesn't help differentiate between them." ?

This is where you need to get creative (while still keeping the system standardised).

Let's run with that same "Small, Blue Veeqo T-Shirt" example from the image above. We release it in a slightly new design every year, so have the following variables to play with:

- Veeqo (brand)

- 2020 (design year)

- T-shirt (product)

- Small (size)

- Blue (colour)

We can add all this together and clip out a few erroneous letters for the SKU to become:

Let's break down another example. But this time with how it might look for multiple product variants in a management tool like Veeqo:

The logic behind these SKUs is as follows:

- GS is for "Gower Shore" (the brand).

- T is for "T-Shirt" (the product).

- CL is for "Classic Logo" (the product type).

- MWL is for "Male, White, Large" (variants of the product).

We can then stretch this out so we replace TCL with TP (t-shirt polo), for example. Or use WWL for women's white large at the end instead of MWL. The combinations are almost endless, and it's built with our own standardised formula in mind.

This format, again, may not quite work for you.

But the key is to assess the unique variables that go into the products in your catalogue. Then put them together into a logical code that is as short as possible while still making sense.

4) Avoid confusing similarities

A final tip is to prevent your SKUs causing confusion by avoiding ambiguities and letters that might be mistaken for numbers.

For example:

An ‘I’ looks a lot like a ‘1’ at a glance, and the letter ‘O’ could well be a zero. But you also may have slightly more nuanced confusing factors – like similar brand names, or products that start with the same letter.

These are the things you need to pay attention to when creating your SKUs to nip confusion in the bud early on.

Aligning SKUs across your sales channels

One of the most critical aspects of good SKU practice is to make sure you only have one SKU for each product variant across every channel you sell on.

Failing to do this pretty much defeats the point of creating SKUs in the first place.

Having two different SKUs is effectively like having two different products, just with the exact same titles and descriptions. And this will cause a major headache at some point along the line when it comes to managing one product catalogue across multiple sales channels.

So here are your two options:

- Standardise your SKUs before adding any extra sales channels.

- If you already sell across multiple channels, standardise and match up SKUs now. Because every product created or sales channel added going forward will contribute to a problem that will appear at some point in the future.

Updating SKUs on a sales channel is usually simple. In Shopify, for example, you can just highlight all your products in the Products page, then click the Edit Products button to bulk edit:

And you'll then be able to select SKU as an option to edit for all products on one screen:

If you have a lot of products, it's probably worth exporting all your product data to CSV, editing the SKUs there and then importing the info back in:

Most popular platforms and sales channels will have similar options and ways for you to update SKUs. Check out this help guide for more information.

Merging products without updating SKUs

We always recommend standardising and aligning your SKUs across every sales channel. But sometimes this just isn't possible due to workload or lack of editable access to SKUs in your sales channel.

A tool like Veeqo's product review and merging feature is the solution here.

Every time you add a sales channel and/or download products into Veeqo, it will:

- Create a new product.

- Try to auto-match it with an existing product in Veeqo via SKU.

- Mark it for review if no matching SKU can be found and it could be a duplicate of an existing product.

You can then review and merge together all these potential duplicates, either individually or by adding to a queue to complete in bulk:

This means you'll then be able to manage products and inventory across every channel – without needing to update any SKUs.

Discover how Veeqo makes multichannel products & inventory simple

Start a 14-day free trial today, no credit card required.

Start free trial

Using SKUs to their full potential

Okay, so we've answered the question "what is a SKU?" and broken down how to create SKU numbers.

Now that you have your SKUs set up, let's look at how best to use them.

1) Inventory tracking

Probably the number one benefit of having standardised SKUs is how much easier it makes tracking inventory across multiple channels.

One product variant, with one SKU, means one central stock figure for each one. And this makes it so much easier to prevent stockouts, overselling and back orders – something your customers will definitely be happy about.

Inventory levels for each SKU can either be recorded in a spreadsheet and updated periodically, or stored in inventory management software and synced in real-time:

Either way, aligned SKUs make this process vastly more simple.

Looking for more inventory tips? Check out Inventory Tracking: Spreadsheets, Automations & Templates!

2) Purchasing and replenishing stock

SKUs make multichannel tracking simpler. But they also make pinpointing when it's time to replenish stock and purchasing new inventory simpler too.

Without SKUs and a central stock figure, you'd never be able to keep on top of when inventory is getting low for each product and its variants.

This allows you to do things like set reorder points per product variant:

Veeqo's system will then alert you when re-order points have been hit:

You can even easily draw up a quick purchase order, and auto-populate all your products low on stock for each warehouse and/or supplier:

3) Conducting stock takes

Stock takes are necessary to make sure your recorded inventory (in either your system or spreadsheet) matches the actual inventory that's sitting in the warehouse.

These can be a major bore. But become next to impossible without SKUs or an aligned product catalogue.

Let's run a stock take for one of our warehouses in Veeqo:

You get a list of products in that warehouse to count, and can easily make changes if any discrepancies are found. But without one aligned SKU per variant, you and your team would be completely wasting time.

4) Helping with pick & pack accuracy

Good, logical SKUs can also help when it comes to order accuracy during the pick & pack process.

For example:

You can use a barcode scanner to scan items during the pick & pack process – picking items from shelves, placing on a cart, and scanning to check for accuracy. But there may be two (or more) similar looking items on the same cart when it's brought to the packing desk – e.g., a t-shirt that's in navy, and one that's in purple.

Logical SKUs will help the packer to quickly identify which item goes into which order – meaning your customers don't end up disappointed and making returns.

5) Identifying your most valuable products

SKUs can contain information about a product’s colour, manufacturer’s name, size or style.

So by keeping track of the most in-demand SKUs, you can reliably know which specific product variants customers buy most often, as opposed to just the products overall.

To do this in Veeqo, we'll:

- Run a product report.

- Group by Variant.

- Then sort by the Net Sales column to give our best performing SKUs:

We can then use this data to make decisions on product variants. So for best sellers, you might want to:

- Increase ad revenue specifically to that variant.

- Push upsells and cross sells to that variant from other products.

- Run specific email campaigns around that variant.

- Switch to having it as the default variant chosen when first opening the product page.

- Factor it into future forecasts and purchasing amounts.

Conversely, we can try to pinpoint why variants at the other end of the scale are performing poorly. All this is near enough impossible if you're selling across multiple channels without aligned SKUs being pulled into a centralised system.

Discover how Veeqo makes multichannel products & inventory simple

Start a 14-day free trial today, no credit card required.

Start free trial

Final thoughts

Taking the time to find the best structure for your SKUs and implement them across your stock will pay off when your system becomes more efficient than ever. Tracking stock levels and automating replenishment is key to keeping products flowing out to customers.

Use the tips and insights above to make the most of your SKUs and keep all products stocked to the right level. You can learn more about the value of barcode scanning in this guide.