Powerful Inventory Management Tools

Improve fulfillment efficiency and customer satisfaction by preventing stock-outs, forecasting customer demand, automating inventory tasks, and keeping inventory up-to-date across your marketplaces, stores and locations.

No monthly cost, completely free to use

What is the Fair Usage Policy?

To use Veeqo’s inventory features, you must ship at least 50% of your online orders using either our shipping rates or your own carrier rates connected to Veeqo.

When you sign up for the Priority plan, the Fair Usage Policy will no longer apply to your account. Use all our features with no restriction!

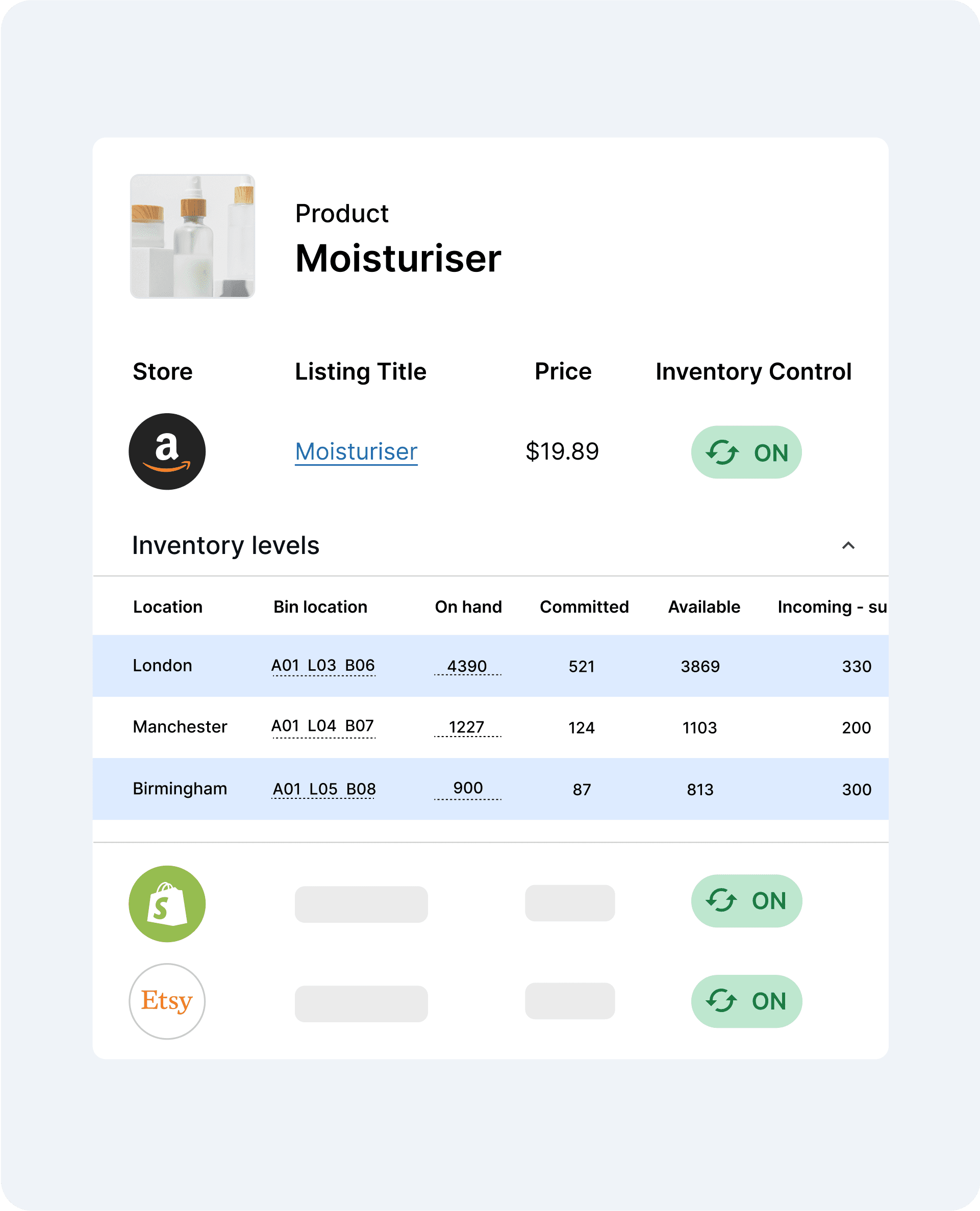

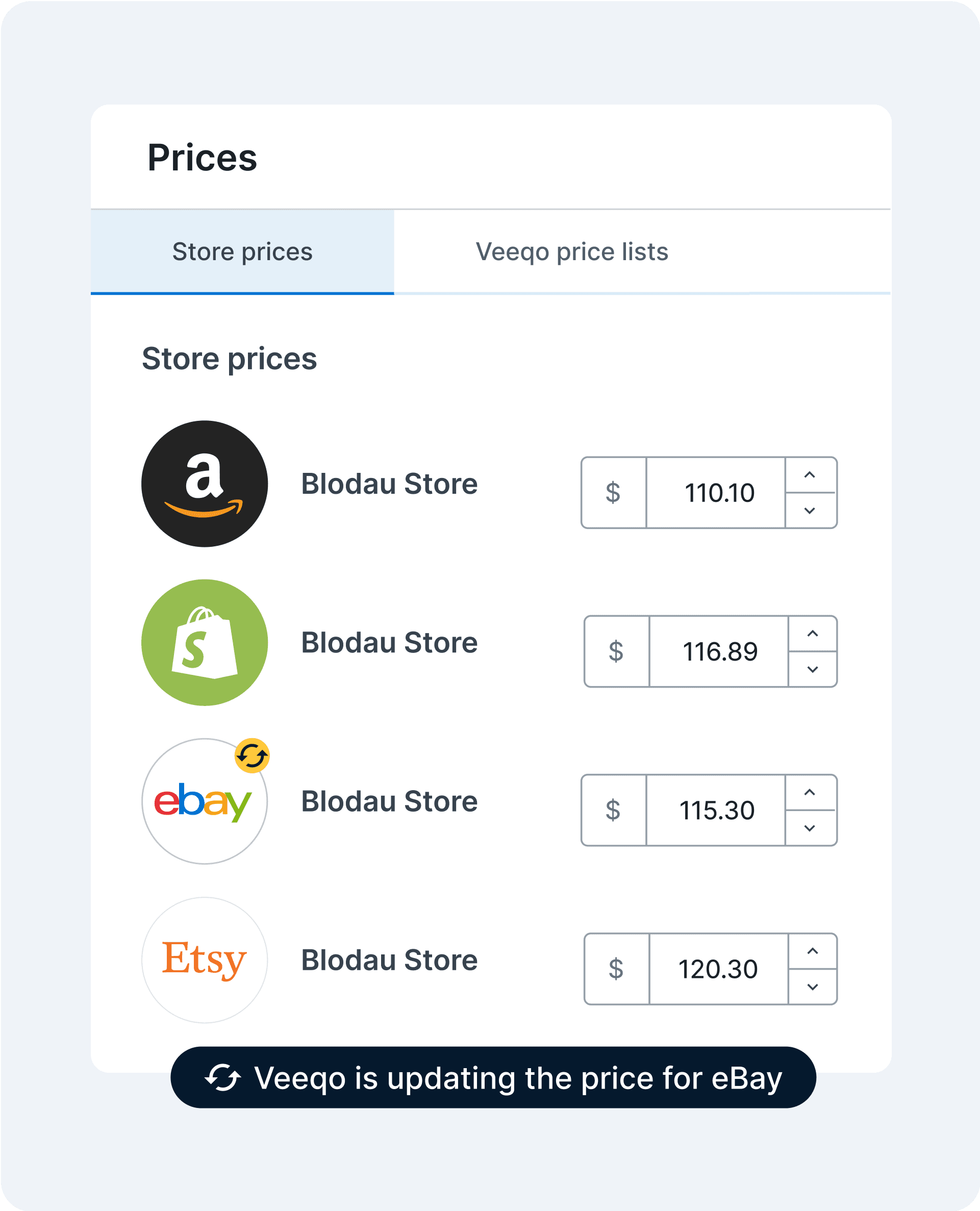

Adjust stock and listing prices in one place

Update stock and prices for products on every marketplace and store you connect to Veeqo from one place, saving you hours of manual admin time.

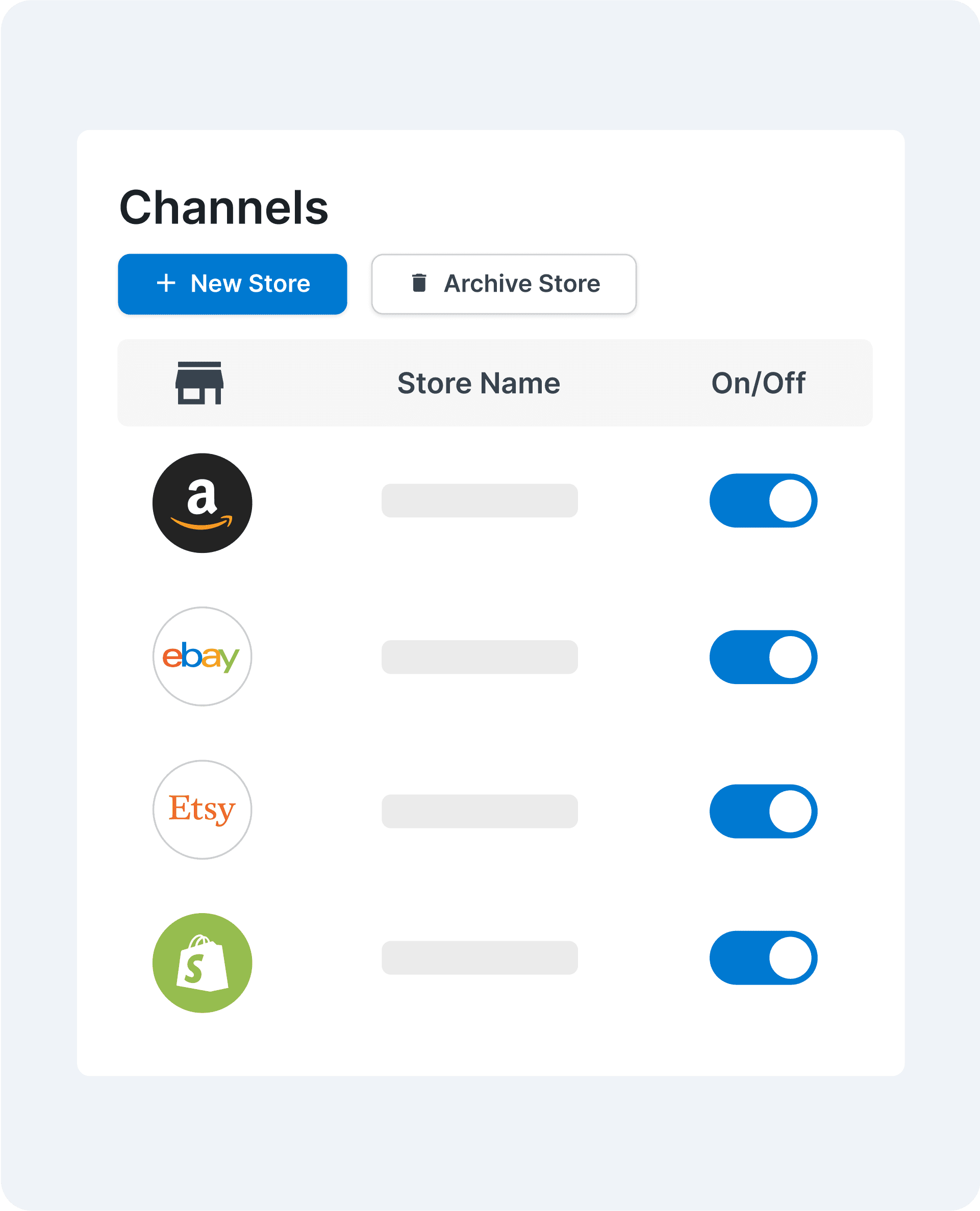

Your carrier, marketplace and store data - all in one place

Veeqo simplifies and scales with your shipping needs with customizable warehouse workflows, trusted carriers, and connections to all selling channels and marketplaces for you require.

Integrates with over 50+ Stores & Carriers

Connect all of your stock levels to Veeqo for active inventory management, demand forecasting and so much more.

eBay

Manage your eBay inventory with Veeqo

Royal Mail

Ship your multichannel orders with Royal Mail

FedEx

Ship your multichannel orders with FedEx

Amazon

Manage your Amazon inventory with Veeqo

Transfer and track stock across multiple warehouse locations

Transfer stock to other locations and track changes in available stock levels made from sales, purchase orders, location transfers, inventory counts and more.

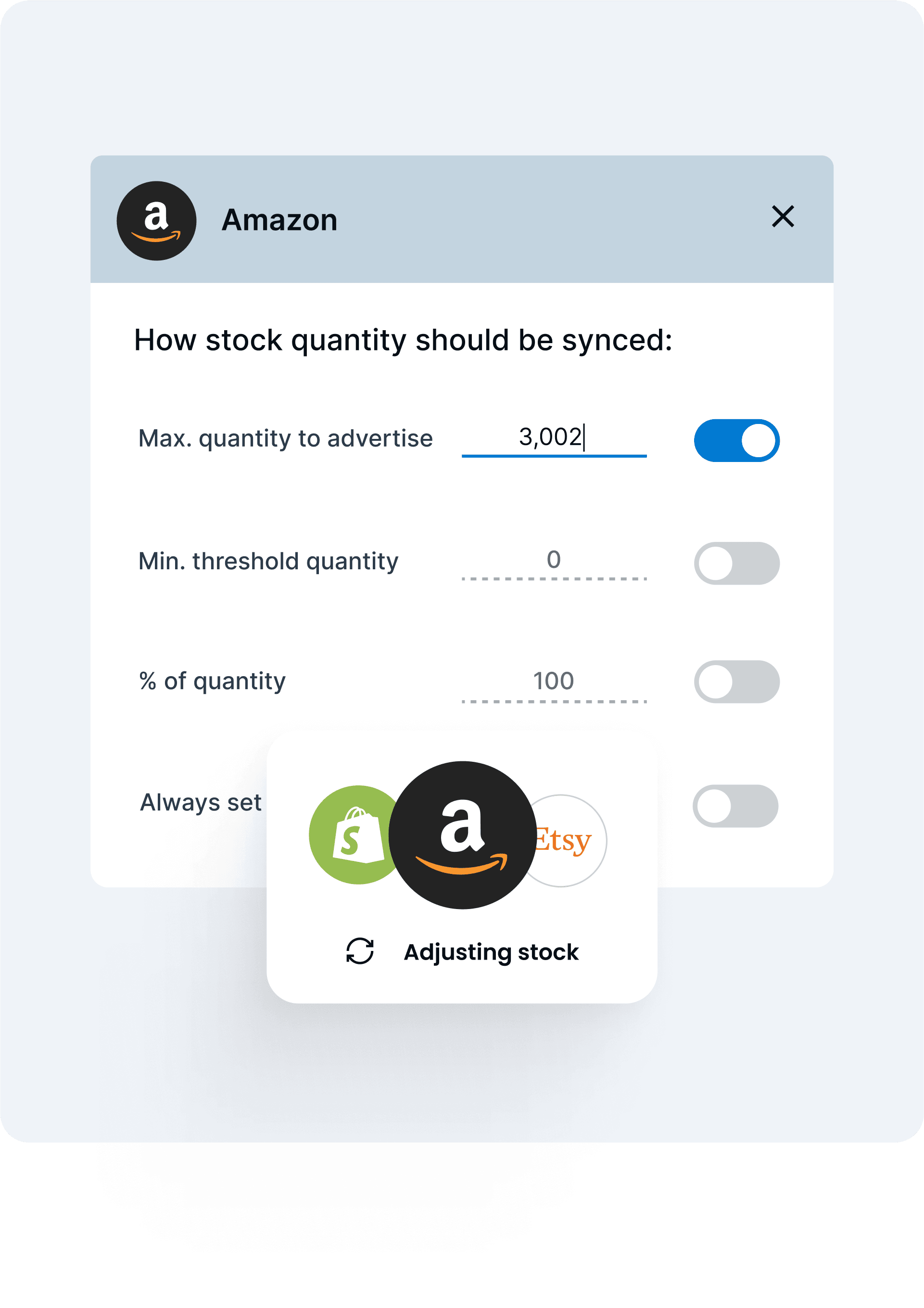

Inventory rules to automate repetitive tasks

Inventory rules works with your stores to adjust and advertise different stock levels across every store you sell on. Inventory rules in Veeqo can:

Create urgency on your listings by showing stock levels that are lower than inventory actually on-hand

Set aside units for retail stores for walk-in customers

Leave a buffer of stock to prevent over-selling

Other merchandising tactics

Meet your Ebay listing limits

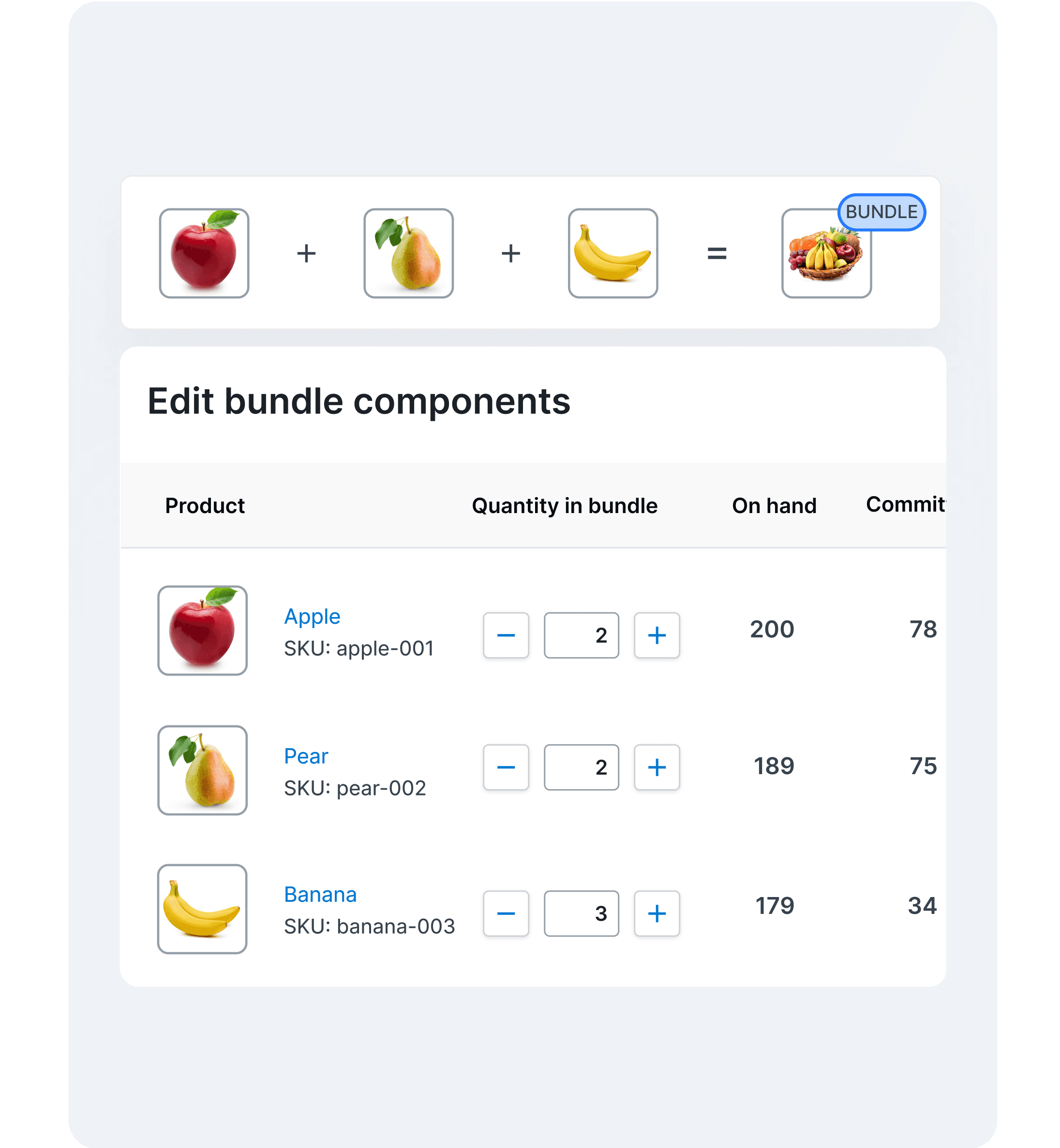

Sell products individually or in bundles

Sell products together for upsells, cross sells and marketing promotions across all your stores.

There's no need to set up stock in pre-packed kits - you can create bundles at any time through Veeqo's inventory page.

If you have old inventory or products you need to sell, bundle them together and let Veeqo track the inventory.

Enterprise-level software

without the price tag

Service

No. Shipments

No. Users

£ Cost

Unlimited

shipments per month

Unlimited

users

£0.00

per month

ShipStation

10,000

shipments per month

10

users

£175

per month

Channel Grabber

10,000

shipments per month

5

users

£249

per month

Shiphero

Unlimited

shipments per month

5

users

£1500

per month

£0.00pm

Unlimited shipments per month

Unlimited users

Pricing information sourced from https://www.shipstation.com/pricing/, https://channelgrabber.com/pricing/, https://shiphero.com/software/pricing. Last updated November 2023.

One decision for your business

that’s a no brainer

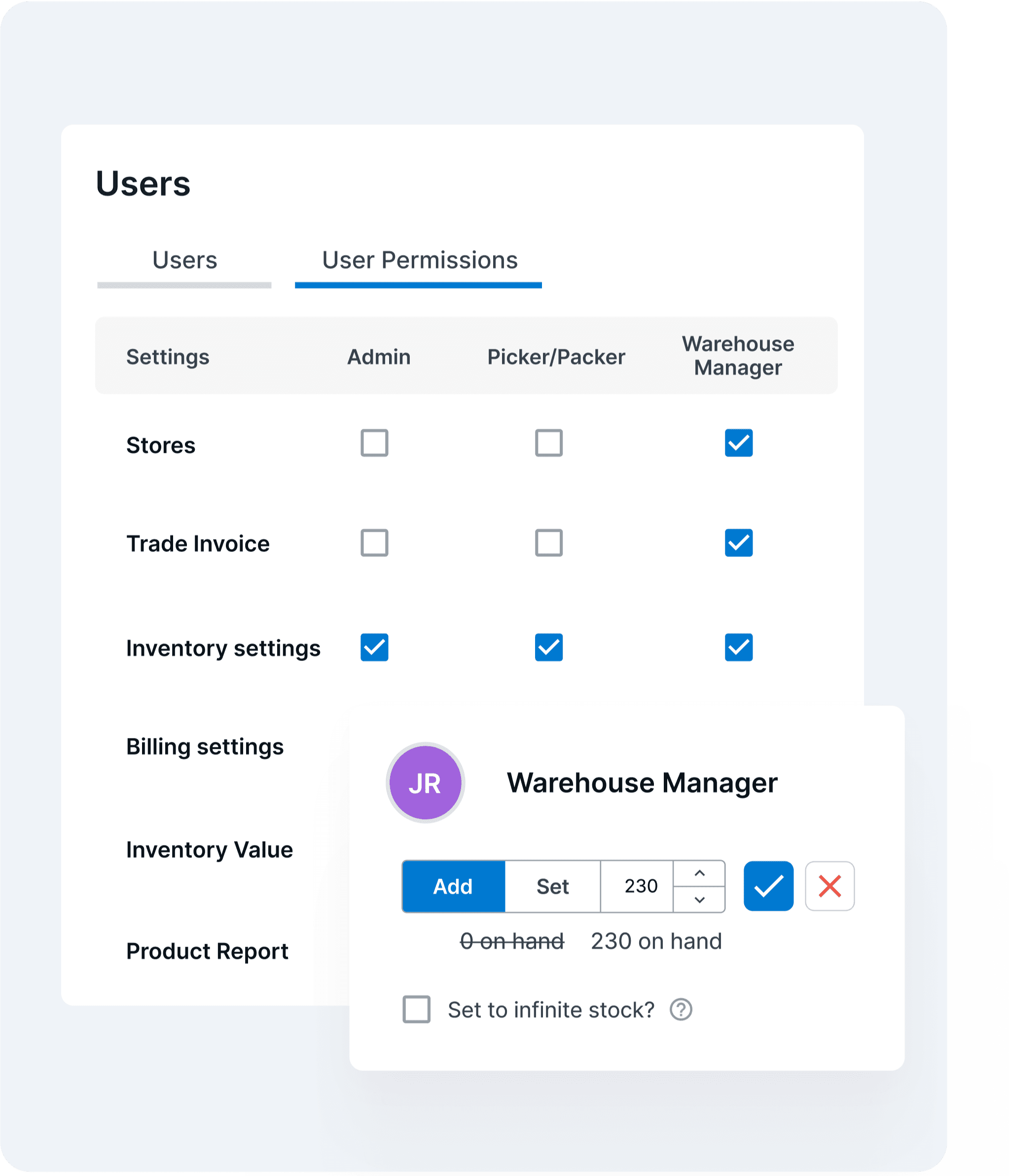

Create, edit, and assign permissions

Adjust account permissions for your team based on preset user roles in Veeqo (Admin, warehouse manager, customer service manager, etc.) or by feature permissions in Veeqo such as:

Store access

Digital picking

Email templates

Rules

Locations

Delivery methods

Reports

"Veeqo is a shipping software Swiss army knife for Amazon Sellers"

As a brand owner and director of multiple other online businesses, and the director of an Amazon agency, it could be difficult for me to handle numerous fulfilment options, sales reporting and inventory management all at once, but Veeqo makes it easy, and it's free.

Huw Morgan, Amazon Seller, Walrus Apparel