Demand forecasting and sales reporting tools

Maximize your sales and profits with our powerful suite of demand forecasting and sales reporting tools. See what product is selling best on which store and make better decisions when it comes to investing in future products.

Data-driven forecasting for data-driven sellers

Forecast upcoming demand for your products based on historical sales performance and easily replenish it with our purchase order feature. You can fine tune your demand forecast based on:

Sales uplift

Stock holding time

Supplier lead time

No. of customer waiting on backorders

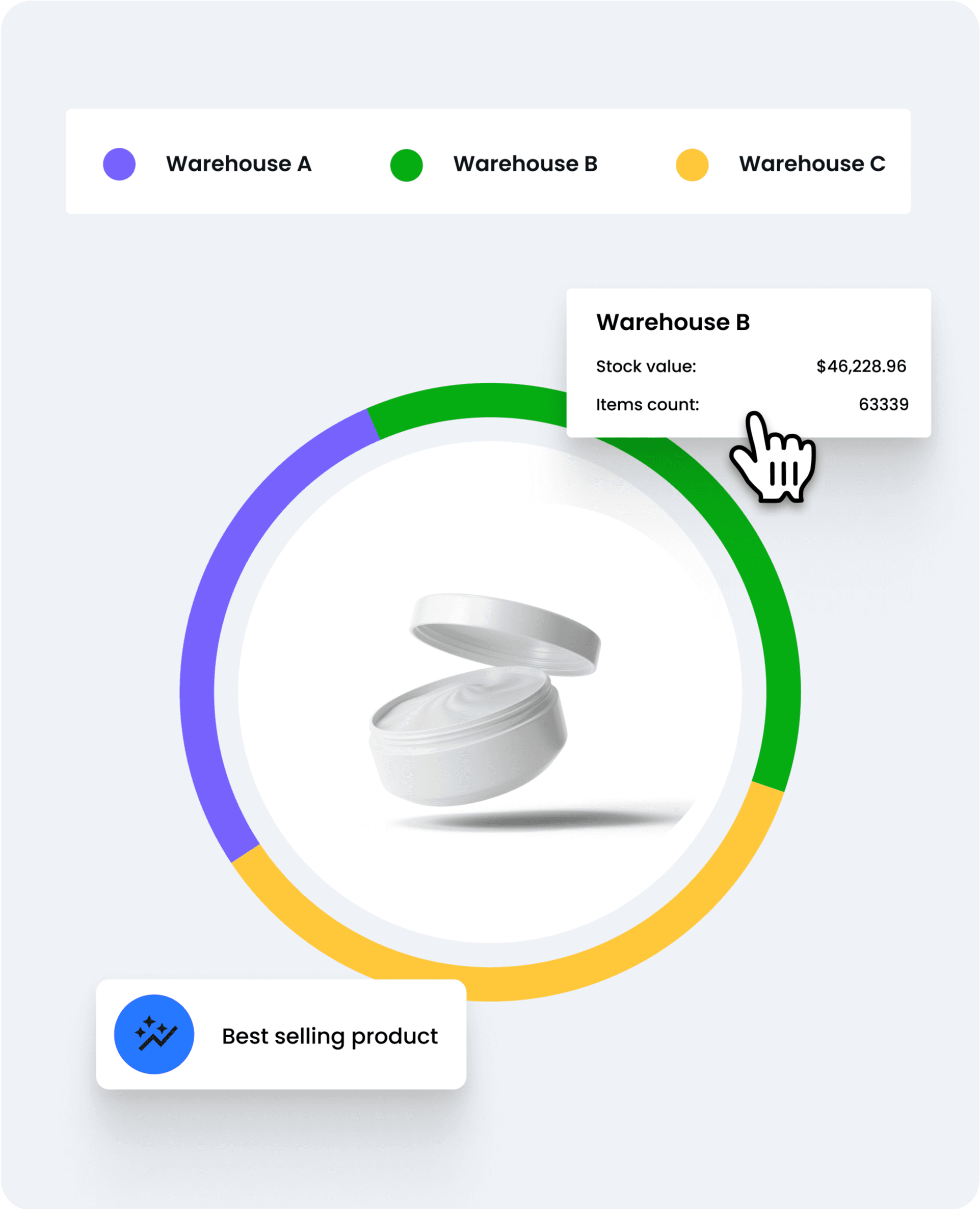

Inventory quantity and valuation reports

Keep track of your total inventory quantity (by SKU) and the value of your inventory by warehouse location. Compare inventory value across multiple locations and always know what inventory to store.

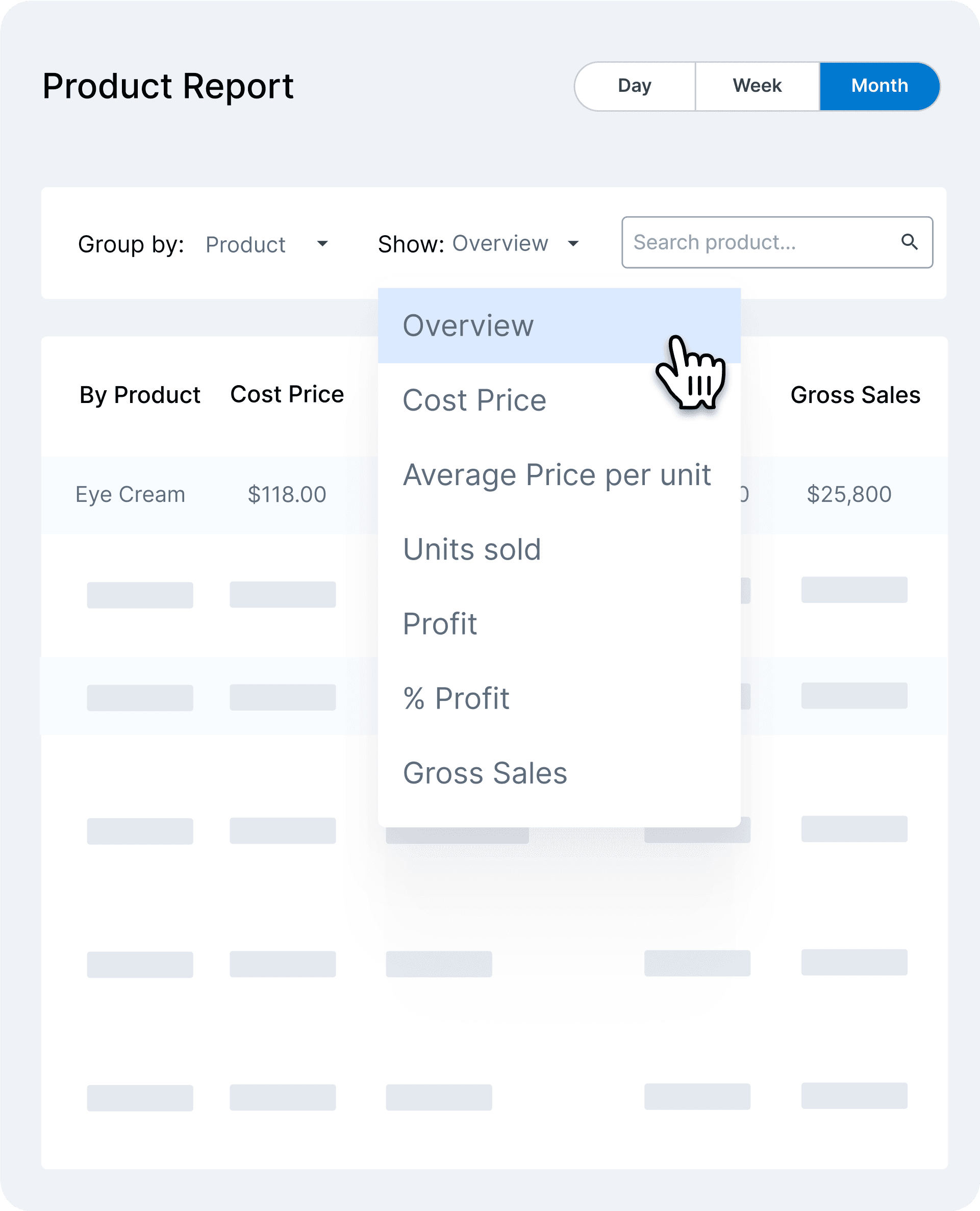

Sales revenue per SKU and by product categories

Discover how your SKUs are performing by seeing your sales revenue by SKU, across every marketplace you sell on.

Filter based on store, order status and product brands to get the data you need.

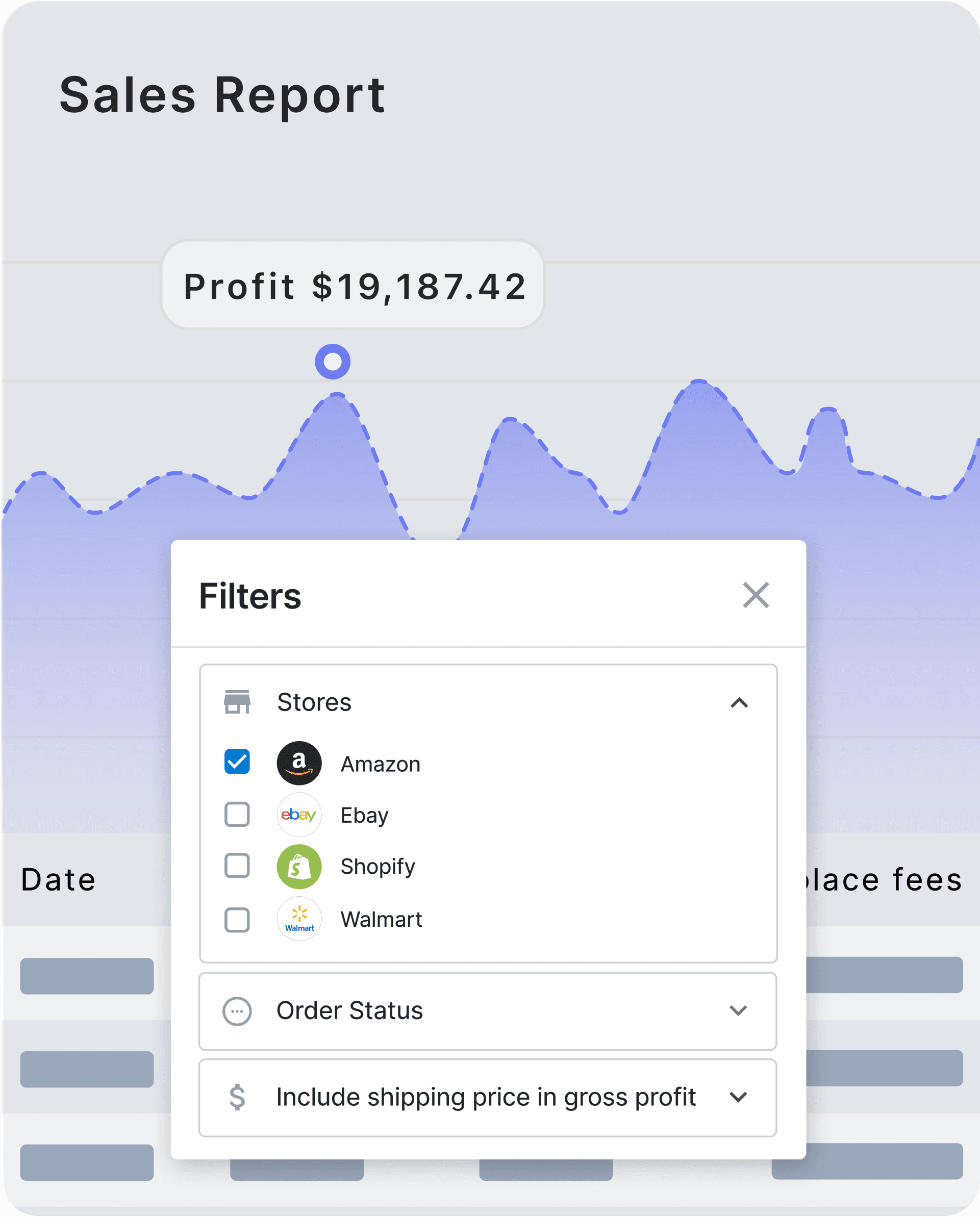

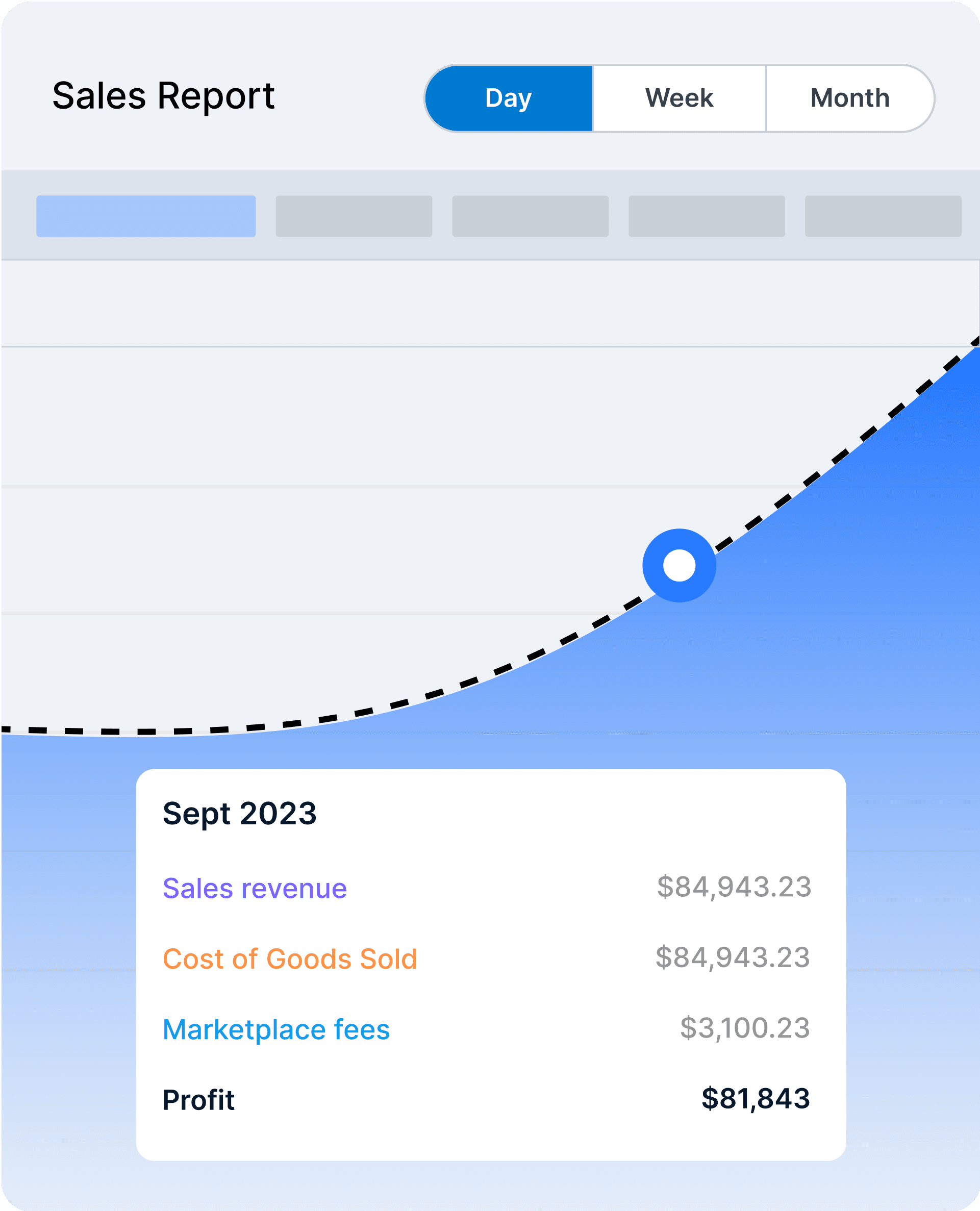

Profitability reports at your fingertips

Get profitability reports for all your marketplaces and products in one place.

Filter by date, marketplace, brands, countries, wholesale and many more.

See your gross/net sales, COGS, profit/gross profit, average order value, total tac and much more to accurately judge the profitability of your business.

Compare sales periods with another point in time.

Now available in Veeqo: Multi-Channel Fulfillment by Amazon

Leverage Amazon’s fulfillment network and expertise to power the growth of your ecommerce business.

With Veeqo’s integration with MCF you can manage your shipping, inventory and fulfillment all in once place.