Inventory Count Best Practices

Understand the best way to carry out physical inventory counts, the advantages of inventory cycle counts and how barcode scanning can help ecommerce businesses.

Knowing how much stock you have on hand is key for any ecommerce business. Get it wrong and you are prone to overselling or overstocking, both of which can hurt your business in different ways. While the idea of keeping on top of your stock may seem simple to small retailers just starting out, it can quickly become more complex. Especially when you start delving into multichannel ecommerce.

What is an inventory count?

An inventory count is a way of keeping track of what products are currently in stock and in what quantities.

Doing an inventory count helps you determine the amount and condition of the products you have in stock in a retail space or warehouse. By carrying out an inventory count you are able to check your actual stock against the figures you have recorded in your inventory tracking spreadsheets or tools. Do they match? If not, you can start asking why, and implement plans and procedures to reduce the discrepancy.

There are several different inventory count methods and best practices. For example, while some companies choose to count stock once a year or quarterly, others carry out rolling inventory counts (cyclic counting).

Why are inventory counts important?

Inventory counts are important because they let you know what you have to sell right now, helping you avoid overselling and stockouts. You can also use the information from inventory counts to inform your inventory forecasting and identify which products are costing you money through overstocking.

An inventory count helps you ensure that your sales tallies and paperwork accurately match the stock you have on hand. In addition, it will help you determine your ‘shrinkage,’ which is the amount of merchandise that goes missing without an explanation.

If you’re selling across multiple channels and across multiple warehouses or retail locations, reliable inventory counts are a must. Not having accurate inventory figures will lead to unhappy customers if they’re waiting a long time for an oversold product.

If you have a small retail shop, you can likely do multiple manual counts at a glance throughout the day. However, once you start to scale your business this becomes impractical. This is why ecommerce retailers looking to scale their business, or add more sale channels, will start to look for more advanced inventory tracking systems.

The difference between a physical count and a cycle count

A physical inventory count is when the retailer closes operations to physically check each item of inventory. With cycle counting, you continuously perform stock counts on a rolling basis, counting small subsets of your inventory on specified days. So a business may count stock section X every quarter, section Y every month and so on.

Cycle counts help by regularly validating your physical inventory against your digital records, ensuring consistency and accuracy. If you cannot close for an extended period of time to perform an annual physical inventory count, this method is often ideal. It also protects against overselling if you have an unexpected surge in sales.

With Veeqo’s digital picking system you can task your picking team to carry out incremental inventory counts during their downtime.

Fewer and fewer businesses continue to do annual physical counts, but it’s still the right choice for certain industries and locations. It allows you to start the next financial year on a clean slate and gives you a dedicated period to set aside for the count. However, you must shut down your shipping and receiving (or account for them), and it takes quite a long time.

If your employees are doing the count by hand, there is a high chance of human error. Give them plenty of time to perform the count, and ensure they get plenty of breaks and snacks.

Some businesses choose to perform a mix of periodic cycle counts and annual counts to closely monitor their stock and stay on top of shrinkage.

One of the key advantages of an inventory cycle count are that:

You don’t have to shut down your business to get accurate figures

It’s easier for your warehouse team to do

You will have more accurate stock counts throughout the year.

Eight tips for carrying out a physical inventory count

With a little bit of planning and staff training, you can make your physical inventory count a smooth process. Use the following tips for your next count.

1. Plan ahead

Whatever methods you use and however often you conduct your physical inventory counts, make sure to schedule them well in advance. Then, start tracking your typical sales downtimes.

For example, many retailers find that mid to late January is slow, whereas the run-up to Christmas is heaving. December is not the time to burden your staff with large inventory counts!

Once you’ve assessed your sales patterns for downtimes, schedule your physical inventory counts.

2. Let everyone know as soon as possible

Once you know when your inventory count should be carried out. You then need to make sure everyone else knows too. This means:

Notifying your team

Assigning extra shifts to relevant employees

Letting customers know if you’ll be closing a physical store during business hours

If you do the count manually, you will need to shut down activity at that location for the entire duration. No stock should be moving in or out during this time to ensure complete accuracy. So there may be others you need to inform due to this.

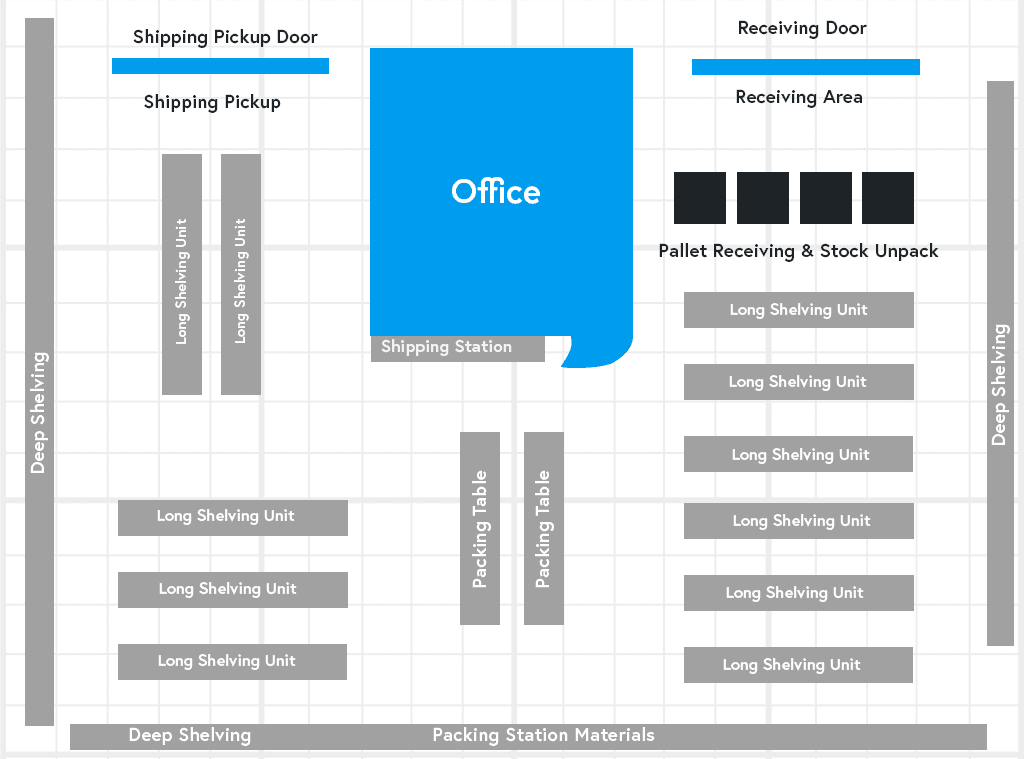

3. Know your warehouse/store layout

It’s always a lot easier to count your store or warehouse’s inventory if you have a clear map of the square meterage you need to cover. If you have an official floor plan, you can use it to plan your attack. If you don’t, start sketching out every detail in the space. Include all of the walls, racks, shelves, display units, workstations, and your backroom. Don’t forget to include any overflow storage and be sure to check the cupboards on and around all computer terminals and stations.

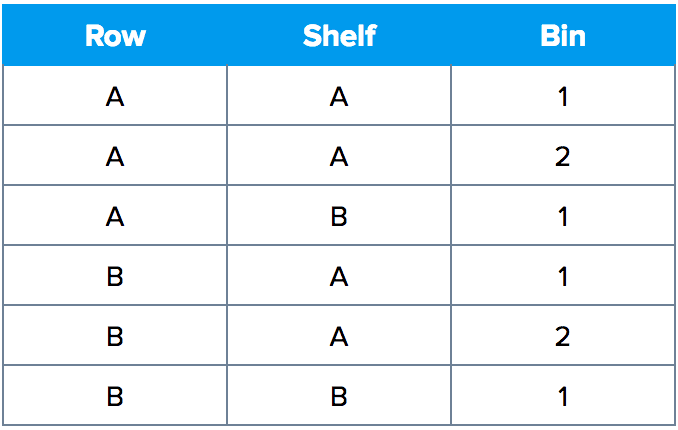

4. Label your warehouse properly

That brings us to the next point – labelling your warehouse. It’s not just essential for an efficient and accurate inventory count, but it’s also a general warehouse management best practice.

Assign each of your displays, racks, shelves, and wall units with specific numbers, and ensure that the numbers match your map. You can then include these numbers on your tracking sheets so you can tick them off as you’re taking your physical inventory count. In addition, you can easily assign different team members to specific sections to complete your count faster on the day.

5. Train your team

While counting inventory may sound like a straightforward task, there are many procedures and systems involved when it’s done right. For a successful and accurate inventory, your staff members need to know exactly what these procedures are and how they work.

Choose one of the following training strategies:

Organise a training session before the date of your count.

Allow time for a training session on the day before any counting begins.

During this training time, take your team members through all aspects of the count, including how to count effectively, what forms to use, and how to use any equipment involved.

6. Use inventory tags

Inventory tags are a great way to easily keep track of what items have been counted. They’re especially useful if you’re completing your count manually.

First, make sure to get two-part tags. Then, simply get your team to fill them out as they conduct the count – attaching one to the relevant warehouse place and keeping the other for reference.

7. Break your team into counting partners

By now, you have:

A dedicated team of people scheduled to work on the day of the count.

A clearly dissected, mapped, and labelled warehouse.

An adequate number of inventory count tags.

It’s time to break your team into counting partners and assign each pair to their

own section of the warehouse. In this method, one person is typically responsible for counting the inventory in each bin in their section, while the other person marks up the count tags with relevant information.

They then return the tags to a central inventory clerk, who will verify the tag information and assign that pair another warehouse section to count.

7) Think about the human side

Finally, it’s crucial that you remember that taking a physical count of inventory tends to be a gruelling task for everyone involved. Your team could be there for a while – endlessly counting and verifying numbers over and over is an exhausting task.

So, it’s crucial to think about the human side of things during the physical count. Make sure there’s ample food and drink available and that staff get regular breaks. Keeping everyone well-fed, hydrated, and rested could prevent a damaging counting error from happening. Try to turn inventory into a fun event – you can host contests, let them listen to their choice of music, and give them gift cards and bonuses for working this arduous shift.

What To Do About Stock in Transit

As you prepare for your physical count, you need to take your in-transit stock into consideration. If you have goods in transit during the inventory period, you’ll need to pay special attention to counting them. This could apply to goods moving between warehouses, goods that have been sold or goods en route from suppliers.

To determine if you need to count your stock in transit from suppliers, you first need to determine if a sale has occurred. If you have paid for the items or agreed to pay at a later date, the passage of title has shifted to you, and you legally need to count this stock in transit. Remember – the title passes when goods reach the FOB point, which means they are ‘freight on board.’

However, if the sales title has not yet shifted to you (perhaps you have ordered the item but not yet paid for them), then you do not need to count them.

The same logic applies when you are selling items to your customers. If the goods have reached the FOB point, then you should no longer count them in your own inventory. These goods in transit now belong to your buyer and should not be reflected in your counts.

When you have more complex inventory needs this is incredibly hard to track manually, as you will find yourself looking at various emails, invoices and spreadsheets to figure out where you are. This is where dedicated ecommerce fulfilment software often proves useful. For example, Veeqo keeps track of all of your inventory all of the time. Including what you have ordered from suppliers.

It’s also important to keep a track of what stock you have ordered from suppliers. Something Veeqo is able to do. This means that you will have complete visibility of inventory you have ordered, and where it is, at all times. Which is key to keeping in control of your inventory.

The Advantages of Inventory Cycle Counts

While a full annual physical count used to be standard in almost all industries, more businesses are moving towards cycle counting, with small counts conducted on a continuous basis. Cycle counting allows you to minimise disruption whilst maintaining accurate counts.

Some of the benefits of an inventory cycle count include:

More agility to fill orders

Cycle counting allows you to count items in smaller batches throughout the year, which reduces variances in your ordering system and results in fewer back-order items. If you want to meet your customers’ needs and increase your profit, you might even schedule monthly counts of your biggest sellers.

Up to date information

If you have an inaccurate inventory count, you might find yourself over-ordering to have extra supply on hand. With this strategy, you run the risk of obsolete stock and increased carrying costs.

You recognise shipping breakdowns quicker

Regular cycle counts give you accurate, up-to-date information about any problems with shipping, receiving, and inventory transfers. This reduces your costs normally spent on expedited shipping as you try to overcome inaccurate inventory records and appease angry customers.

Reduce errors and theft

When you count more frequently, you can discover errors and discrepancies more quickly. You can also get a quicker grip on theft so you can take the appropriate countermeasures.

Less disruption

An annual inventory count takes a long time and throws your normal systems into disarray. It’s often an all-night slog that wears out your employees – you might even need to bring in extra hands. However, with a cycle inventory count, only small batches are counted at a time. You don’t need to shut down your operations, and the counting process is integrated into your normal workflow.

How to Do a Cycle Inventory Count

When it comes to your warehouse efficiency, moving to cycle stock counts can be a game-changer. With cycle stock counts, you assign your team ‘partial’ stocktakes or inventory counting tasks to complete on a regular, continuous basis. This means that your inventory gets counted in chunks throughout the year, allowing you to avoid

For example:

Let’s say you have two warehouse workers responsible for inventory counts – Bob and Jenny. Here’s how a cycle stock count could work:

Week 1 – Both Bob and Jenny are each assigned 10% of your total inventory to count during shift downtime.

Week 2 – Bob and Jenny are assigned an additional 10% each, excluding inventory already counted.

Weeks 3-5 – Repeat until they count the total inventory– 50% by Bob, 50% by Jenny.

By simply assigning your team small, weekly counting tasks, just two staff members can quite easily count your entire inventory every five weeks.

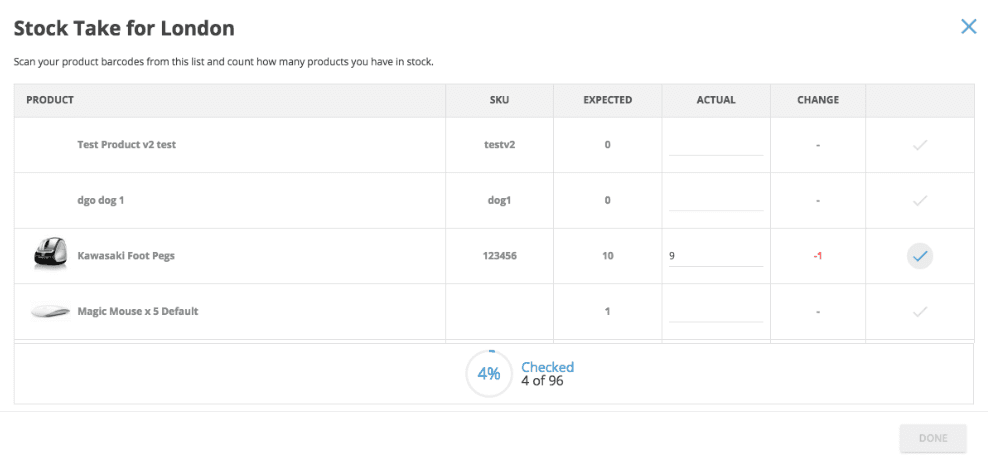

The benefits of a using a barcode scanner for inventory counts

Using barcode scanners for cycle counts can add yet another layer of efficiency to your physical inventory checks. They completely eliminate the need for tags or messy paperwork, and allow your team members to complete their weekly counting quotas quickly and accurately.

Here’s how counting with scanners typically works:

Bob finds some downtime on shift and decides to complete part of his weekly counting task.

He grabs a scanner, logs in, and opens up the inventory count section.

A list of the products that have been assigned to him for counting appears.

Bob heads to the bin location of his first product, scans its barcode, and starts counting.

Any inventory discrepancies are corrected by Bob right there on the screen.

He then moves on to the next product on his count list.

Bob can get through as many products on his count list as he likes until he’s needed back at his typical warehouse station, such as picking or packing.

Learn more about Veeqo’s inventory management software for ecommerce.

What to do after an inventory count

Now that your inventory count is complete, it’s time to follow up on the information you have learned throughout the process.

Check for obvious errors (and investigate them)

Update your inventory report spreadsheets

Compare your data against previous inventory count

Identify issues and plan action to fix them

Possible reasons for discrepancies

No matter what you do, there will always be discrepancies in your stock count. Theft, damage, and simple human error can all affect the numbers. Most businesses have a specific percentage of ‘shrinkage’ they aim for, but if you notice that your shrinkage is much higher than your goal, you need to implement new receiving and storage policies. You may also have a security issue on your hands.

On the other hand, if your shrinkage is much lower than expected, you may have made an error during the count itself. Having an auditor on hand can help pinpoint issues with your methods and results.

Here are some of the most common reasons for discrepancies from an inventory count:

Theft – Sadly, the most common cause of discrepancies is theft. Even if you think you can trust your employees, theft is always a reality in warehouses.

Loss – Just like at home, items can get lost in a warehouse setting. If your staff is losing or misplacing stock, you need new policies in place to get this under control.

Human error – Similar to loss, mistakes can happen in any warehouse setting. If you do not have robust systems in place, your employees can easily mishandle and miscount stock, receiving and/or shipping it incorrectly.

Counting mistakes – Of course, some of the errors can occur during the stock count itself. Using a scanning device can help take some of the human error out of stocktaking

The information you learn during your stock count can be extremely valuable. It can tell you if you are dealing with internal theft, careless mistakes, or a combination of both. That’s why it’s crucial to make the entire process as accurate and effective as possible. It’s also why so many businesses are making the switch to cycle counts.

We hope you have found this guide interesting. If you believe your business needs to move to a more advanced form of inventory management, then you should consider Veeqo. Veeqo is the complete ecommerce solution, handling your inventory management, warehouse operations, and shipping integrations. You can try Veeqo out by either signing up for a free trial or booking a demo today.

About the author

This article was written by Michelle Lau, Head of Product at Veeqo. Michelle leads a team of product managers to make sure Veeqo is the best order fulfillment tool for ecommerce retailers.

Knowing how much stock you have on hand is key for any ecommerce business. Get it wrong and you are prone to overselling or overstocking, both of which can hurt your business in different ways. While the idea of keeping on top of your stock may seem simple to small retailers just starting out, it can quickly become more complex. Especially when you start delving into multichannel ecommerce.