All-in-one Order Management System

-

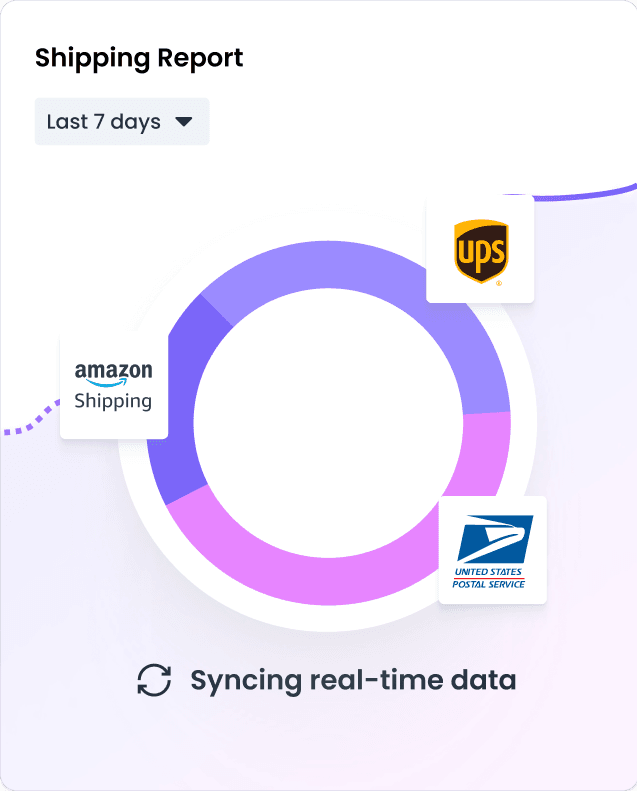

Order management system with 21+ direct integrations

-

Setup order workflows for repetitive tasks

-

Find all your orders quickly in one place

-

Deliver more happy customers

All your tools, one platform

Order management & fulfillment toolsx

Multi-channel order management

Track and fulfil orders from all your sales channels with 21+ direct integrations.

Order workflows that save time

Setup workflows based on triggers like delivery option selected, value and weight.

Returns management built-in

Manage customer service returns and refunds in one place.

Wholesale management

Manage your wholesale orders and automatically keep your inventory updated.

Vital order reports at your fingertips

Generate order, sales and fulfilment reports for data-led decision.

Optimize order fulfillment operations

Having your inventory and shipping in one platform helps speed up your fulfillment.

Shipping software built-in

Bulk print labels, ship your orders & track your inventory in one place.

Digital picking ready

Upgrade your fulfillment with digital picking using our scanner.

“Perfect solution for our inventory management”

We have been using Veeqo Since 2018. We use multiple marketplaces (eBay, BigCommerce, Amazon, etc.), and Veeqo provides the perfect solution for our inventory management needs.

Read story

Ravi

Founder, TCO

Effortless inventory control.

Veeqo automatically monitors every movement of every stock item—all in one place.

Order management system features

Veeqo connects to all of your ecommerce channels, warehouses and locations.

Multichannel orders

Connect your ecommerce, marketplace and offline sales channels into Veeqo’s order management system and view every order in one place.

Wholesale management

Create your wholesale orders and automatically keep your inventory updated. Take orders by phone or mail, set individual or group price lists, minimum order amounts and apply discounts.

Returns management

Manage all your returns and refunds in on place across your customer service, warehouse and finance teams. Issue full or partial refunds and reasons for return. Put items back into stock or write them off.

Veeqo is Free

We’re able to provide Veeqo for free because we benefit from shipping volume passed to our partner shipping carriers.

Unlimited orders

No Shipping label limits

Unlimited users

No monthly cost

Easily Fulfill Your Orders

Easy to use order management connected across all your channels.

Bulk print hundreds of shipping labels

Get a single view of orders from your ecommerce store, online marketplaces and every other sales channel. Then quickly print hundreds of shipping labels with one click.

Create branded custom invoices

Use Veeqo’s built-in templates to create stylish invoices, packing slips and picking lists in seconds. Allowing you to design stunning communication that has you standing out from the crowd.

Find orders in record time

Save and share custom views, apply filters or use a USB/Bluetooth Barcode scanner to display a specific order. Meaning you can find any order at lightning speed.

Order management reporting

Instantly run detailed sales reports

Get business-critical data in seconds. Veeqo lets you run detailed sales reports broken down by channel, store, product, category, order status or by specific team members.

Streamline your accounting

Push inventory, sales and purchasing data from every channel directly into your Xero, Quickbooks Online or Quickbooks Desktop accounting software.

See complete order history

Create accountability and visibility like never before with easy access to a complete record of every action taken on each order.

Advanced order management system features

Auto-print on specific printers

Route different documents to specific printers. Set invoices to automatically print on an A4 device, while labels go to your thermal – all without a PDF download in sight.

Create internal order notes & tags

Clearly communicate any special requirements or VIP customer orders by creating an unlimited number of internal notes and tags. You can even add notes to individual line items in an order.

Prioritize orders with advanced filters

Easily organize orders by applying advanced filter options. Sort by store, delivery method, destination, Prime, order weight, items per order, inventory locations, order date, date shipped or any way you want.

Run a cloud-based operation

Access Veeqo’s cloud-based software from anywhere with an internet connection – via desktop, tablet or smartphone app.

Take control of warehouse management

Use Veeqo’s advanced Warehouse Management System features to organize, pick, pack and ship your inventory with masterful efficiency and speed.

Connect physical stores

Connect Shopify POS or Vend point of sale systems to integrate sales and inventory from any number of physical stores to Veeqo.

Keep on top of returns

No need for messy spreadsheets to keep track of customer returns. Easily see the return’s status and trigger refunds.

Re-ship lost packages

Keep customers happy by quickly re-shipping any orders that get lost in transit, with the option to upgrade the service it’s shipped by.