7 Essential Warehouse KPIs to Start Tracking For Optimal Performance

Last Updated: June 2024

You could be shipping orders to customers faster and more efficiently. But without tracking your warehouse performance, you'll never know how to improve.

Warehouse KPIs (key performance indicators) are the answer.

They allow you to set benchmarks for month-on-month improvements and help identify areas that, when combined with a solid procedure and warehouse management software, will directly affect both overall business costs and customer satisfaction.

In this guide, we cover seven of the most important warehouse KPIs you need to start tracking now.

Table of Contents

Receiving Efficiency

Picking Accuracy

Carrying Cost of Inventory

Inventory Turnover

Rate of Return

Backorder Rate

Order Lead Time

Creating a Warehouse KPI Dashboard

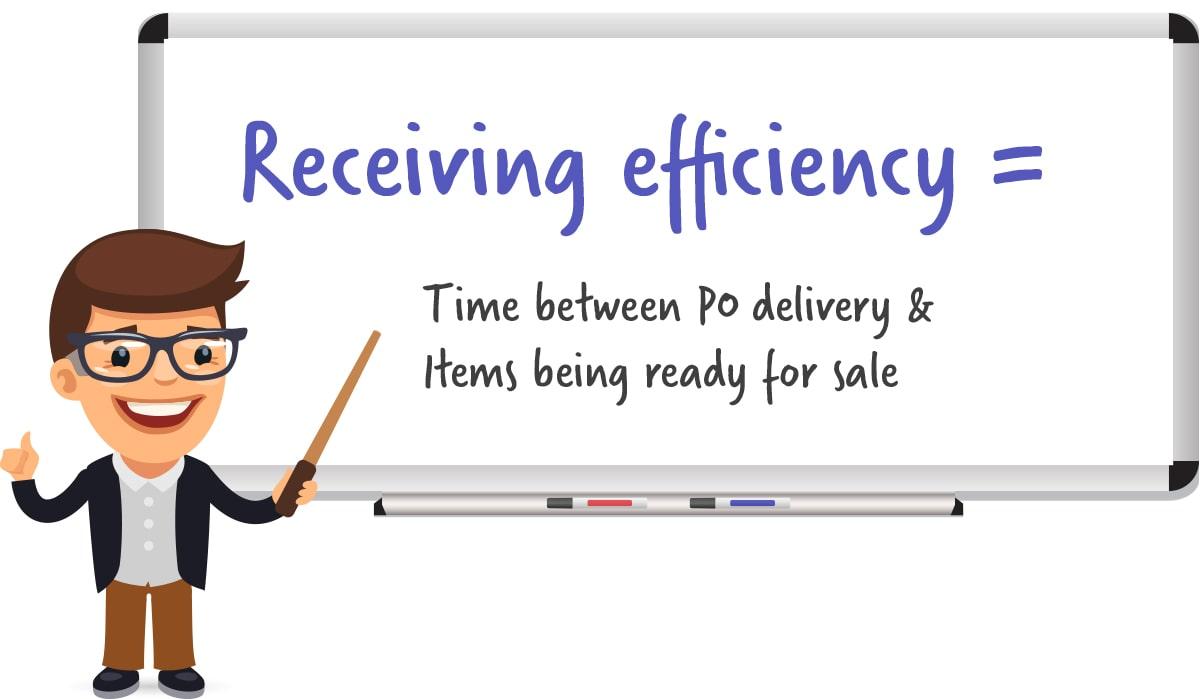

1. Receiving efficiency

A warehouse operation starts with receiving and booking incoming stock.

This process can involve multiple deliveries, customer returns, and return-to-vendor stock. Tracking this with specific KPIs ensures efficiency.

Key metrics to track:

Time taken for received stock to be counted, booked in, and ready to put away.

Tips for improving receiving efficiency in Warehouses:

Systemize the process and assign the task only to trained staff.

Create unique SKUs for individual product variants.

Assign each SKU to a specific warehouse bin location for quick put away.

It’s a good idea to record exact timestamps of all delivered stock. Then record another timestamp as soon as this stock is ready for putting away.

You can then calculate an average for the month and compare to previous performance.

This is one of the warehouse KPIs a quality barcode scanner can help drastically improve too.

The Veeqo Scanner, for example, can be used to scan each product as a new delivery arrives in the warehouse. Then, as soon as a product is scanned, you'll be able to choose the quantity that's arrived in the purchase order and book the figure into active inventory right there and then.

Any stock needed for backorders will get siphoned off for those. The rest are instantly updated across all relevant sales channels managed by Veeqo.

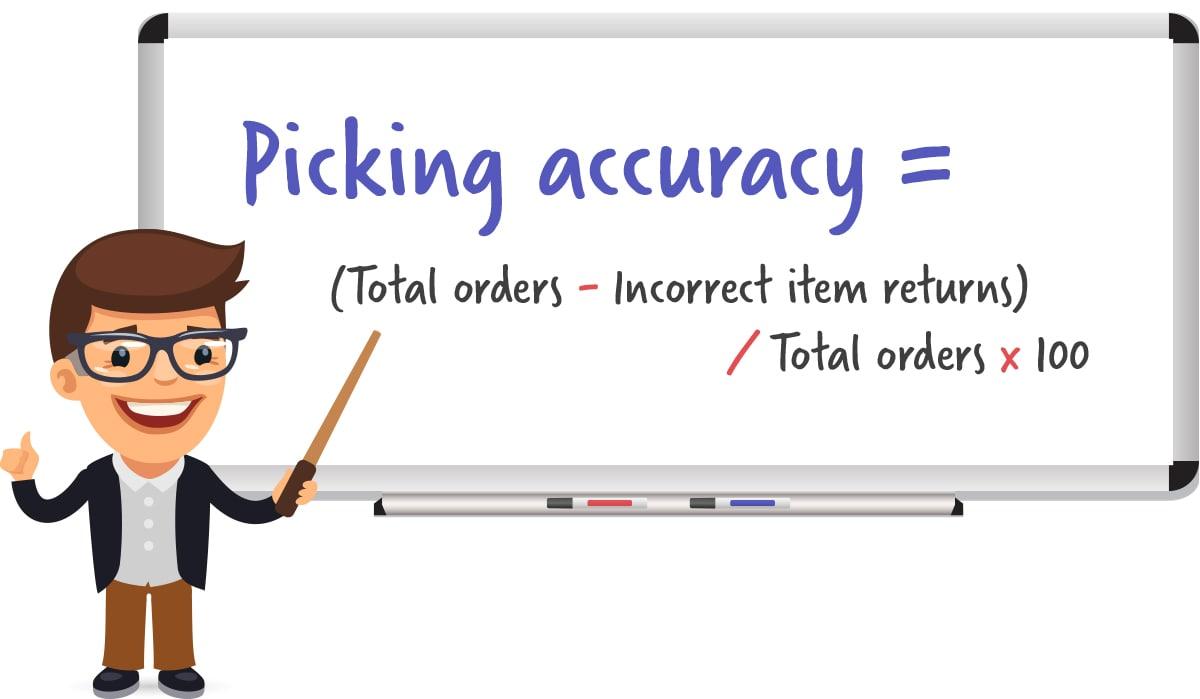

2. Picking accuracy

This leads us nicely onto another vital warehouse KPI: picking accuracy.

Picking accuracy is crucial for minimizing returned items and associated costs. It directly impacts customer satisfaction and operational efficiency.

So this is something that can again have a huge impact on costs and customer satisfaction.

Key metrics to track picking accuracy

To calculate picking accuracy we can use some data taken from the ‘rate of return’ KPI (see below) and total order number in the following equation:

This then gives a percentage of the number of orders that were picked correctly.

Tips for improving picking accuracy

Organize and set up your warehouse logically.

Use appropriate picking systems for your operation.

Invest in minimizing labor turnover to retain experienced pickers.

Adopt a digital pick & pack system with barcode scanners.

3. Carrying Costs

The longer inventory stays in the warehouse, the more it costs a business. But it’s essential to be able to put a quantifiable number in place here as one of your warehouse management KPIs to help you understand and minimize these expenses.

Total carrying costs is the sum of everything it costs a business to hold its stock over a certain timeframe.

Key metrics to track carrying costs

Cost of capital

Storage costs

Equipment

Software

Materials

Taxes

Tips for improving carrying costs

Embrace automation to reduce labor costs without sacrificing productivity.

Improve inventory forecasting to limit the time inventory sits in the warehouse.

Work to reduce inventory shrinkage.

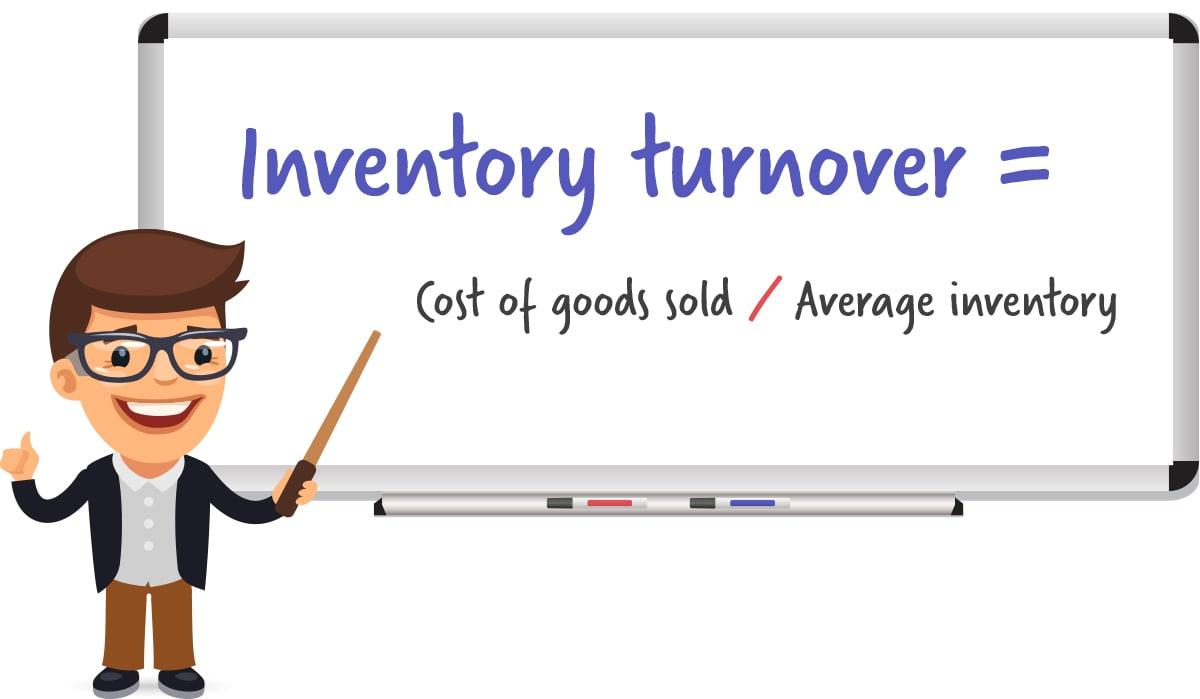

4. Inventory turnover

Inventory turnover measures how often you sell out your inventory. A high turnover rate indicates efficient inventory management.

Inventory turnover is another vital warehouse management KPI and ties in quite closely with carrying cost of inventory.

It is basically the frequency at which you sell out your inventory. In other words, how quickly you sell and ship stock once it’s been put into storage.

Obviously, this is one of the warehouse KPIs you’re looking to keep high and increasing. The faster you move stock, the less it costs to store it and the more profit you can make on it.

Key metrics to track inventory turnover

Your inventory management system will usually provide a figure on this for you. But you can calculate inventory turnover via the following formula:

Keeping track of this performance metric enables greater insight into the popularity of certain items to gauge future buying practices.

Tips for improving inventory turnover

Master inventory forecasting skills.

Identify slow-moving stock and implement reduction strategies.

Keep track of industry standards and trends.

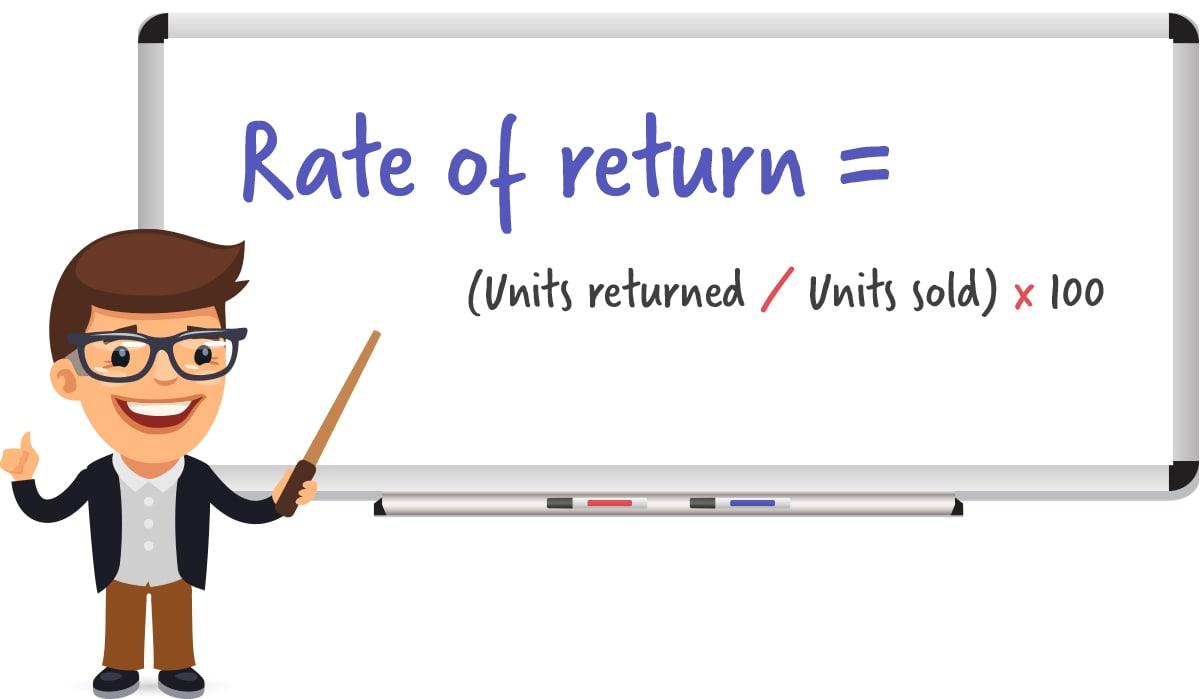

5. Rate of return

The rate of return determines how often items are being returned by customers. Segmenting this KPI by reason for return provides valuable insights.

Key metrics to track rate of return

Track the percentage of returned items segmented by reason (e.g., incorrect item, buyer’s remorse).

You can use the following equation to analyze each one:

This way, the warehouse or operations manager can start looking at exact reasons why this KPI may be high and put into place strategies to resolve.

For example, a lot of returns due to an incorrect item indicates the picking process needs looking at. Whereas a lot of buyer’s remorse returns may mean something in the sales channel product description needs addressing.

Tips for improving rate of return

Ensure product descriptions are accurate.

Train staff on your systems and product catalog.

Store products to minimize spoilage and damage.

Use barcode scanners to confirm accuracy before shipping.

6. Backorder rate

A high backorder rate indicates poor forecasting and inventory tracking. It’s crucial to minimize backorders to enhance customer satisfaction.

A high backorder rate means a lot of orders are coming in for items that aren’t in stock.

Of course, sudden unexpected rises in demand can account for this, but if the backorder rate KPI is consistently high then it’s likely a result of poor forecasting and inventory tracking. Specialist inventory and warehouse management software like Veeqo, can help with these things.

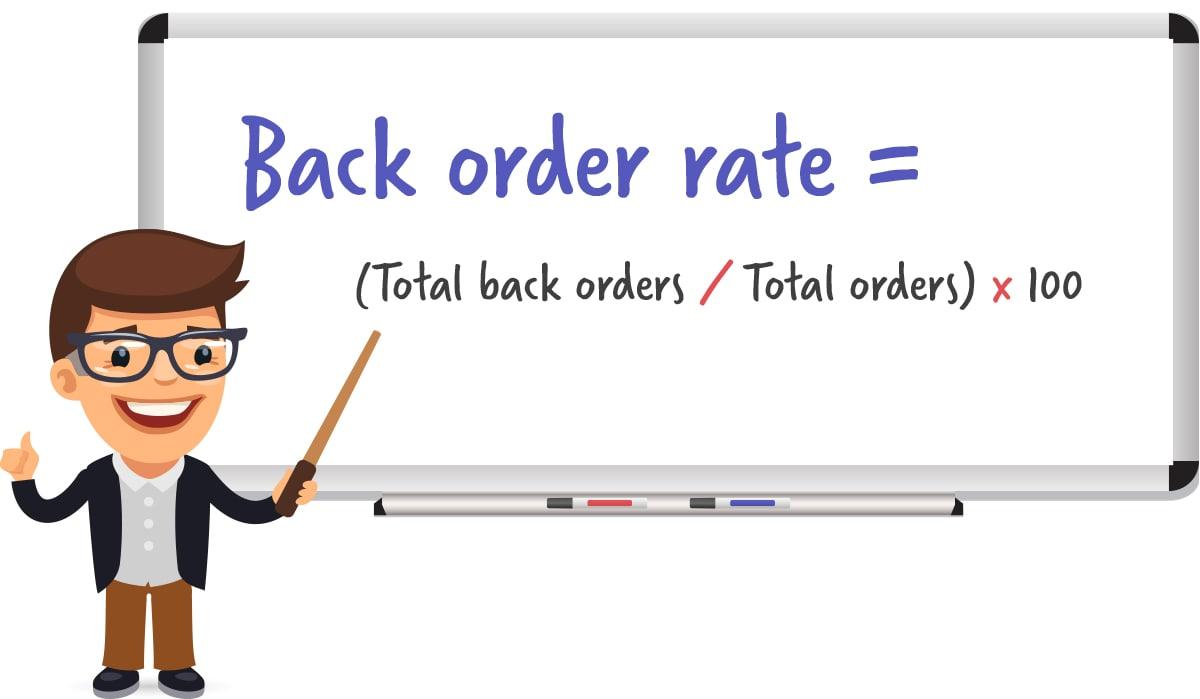

Key metrics to track backorder rate

Either way, backorders create a really bad experience for customers and should be tracked and minimized. You can use the following equation:

Tips for improving backorder rate

Use data-driven forecasting.

Determine proper reorder points and safety stock.

Implement best inventory tracking practices.

7. Order lead time

Order lead time is the average time it takes for customers to receive orders after placing them, and feeds into backorder rate. Lowering this time improves customer satisfaction and retention.

The lower you can get order lead time, the happier your customers are going to be.

As long as items also arrive in perfect condition, optimizing order lead time can also have a direct effect on a more general KPI: order cycle time. This is the amount of time between customer orders - bringing improved retention.

Key Metrics to Track

Average time from order placement to delivery.

Just looking at the popularity of Amazon Prime illustrates this well. According to Business Insider, Prime members spend almost twice as much on Amazon as non-Prime customers.

Tips for improving order lead time

Optimize order management processes.

Choose the right picking system and consider digital batch picking.

Use faster shipping carriers and services.

Bulk print your shipping labels.

Bulk ship orders to increase daily output.

It's worth noting, that one of Veeqo's sellers, A1 Great Deals, has saved 6-hours per day in time by printing up to 100 labels in one-go with Veeqo's bulk printing feature.

Mike Truffa, the owner of A1 Great Deals, told us: “Ever since we’ve been able to print 100 labels at a time with packing slips, it’s saved hours of time a day.” he went on to say “On the amount of shipments we’re doing right now, I would have been printing labels way past 5pm, starting at 9am. It would take all day.”

Mike continued to tell us it now only takes him two-hours to print all of his labels and packing slips, a time reduction of 75%, leaving him with an extra six hours per day to complete other business tasks.

Creating a Warehouse KPI dashboard

To track all your KPI's, it's worth creating a warehouse KPI dashboard.

This can be a spreadsheet or other form of tracker to give you one place to update and monitor performance. Meaning you're more likely to track and implement improvement strategies on a regular basis.

Veeqo users can see a KPI dashboard to track a number of business metrics, including sales and orders data, warehouse performance as a whole, and as individual team members.

Of course, there are many more warehouse KPIs to keep in mind. But these are seven of the key ones that are vital to keep track of.

Sign-up to Veeqo today and gain access to our powerful suite of inventory and warehouse management tools, for free. You'll also be able to access the lowest commercially available rates, based on our pre-negotiated pricing from UPS, USPS, FedEx, and DHL and up to 5% back with Veeqo Credits.