Inventory Storage

Inventory storage is critical to long term retail success. Fail to look after your stock properly, and you run the risk of it getting lost, stolen or damaged - wasting cash that could be used on other important business expenditures.

So this chapter is all about how to most efficiently store, organize, maintain and generally preserve the life of your inventory.

Broad inventory storage options

The first thing to assess is exactly where you’ll be storing inventory. To do this, you typically have a few options.

1) Dropshipping

Dropshipping is a way of purchasing inventory where the retailer doesn’t keep any of the products it sells in stock. Instead, items are purchased from a third-party supplier as and when each customer order comes in, with the supplier shipping products directly to the customer.

It therefore entirely negates the need for inventory storage or keeping stock on-hand.

Pros:

Inventory storage is entirely taken care of by the supplier.

Supplier is liable for any inventory shrinkage.

Lower overall costs of not needing a warehouse, 3PL or fulfillment team.

Less risk when starting out.

Cons:

Little to no control over product quality or branding.

Puts someone else in control of how well products are stored.

Shipping speeds can be incredibly slow.

Highly competitive with razor thin margins.

Best for: Startup retail brands that want to test the waters before investing in bulk inventory.

2) Third-party logistics (3PL) service

A third-party logistics (3PL) service allows retailers to effectively rent space in another warehouse. You can then send inventory units directly to the 3PL location for them to store and ship on your brand’s behalf.

This usually incurs housing and shipping fees, but again eliminates the need to worry about having to store inventory.

Pros:

Inventory management is entirely taken care of by the 3PL service.

Can take advantage of bulk inventory discounts without the need for a self-fulfillment warehouse.

Usually involves significantly faster shipping times and more control over product quality compared to dropshipping.

Cons:

Monthly storage fees can eat into profits for slow moving stock.

Trusting someone else to ship products on your brand’s behalf.

Usually requires investing in bulk stock quantities.

Best for: Growing retail brands that have proven, consistent sales and want to buy stock in bulk without a dedicated warehouse.

3) Self-fulfillment warehouse

A self-fulfillment warehouse is a location set up by a retailer in order to specifically store its own inventory and ship orders.

This usually comes with significant up-front investment of both capital and time - like signing a lease and hiring a team. But if the sales are there and numbers make sense, then the result is more control and lower operational costs in the long run.

Pros:

Complete control of the fulfillment experience delivered to customers.

Initial investment can result in long term savings compared to a 3PL.

Cons:

Usually involves signing a long term lease, which can be risky.

Will need to hire and train a team, and possibly invest in WMS software.

May require moving to new locations several times as the business grows.

Best for: Established retail brands planning for long term growth.

Setting up your warehouse

The main goals of setting up your warehouse for optimal inventory storage are:

Safety. Any inventory should be stored safely to prevent both injury to staff members and damage to the inventory itself.

Security. Warehouses with large amounts of valuable stock will be a target for thieves, so this should be prevented as best as possible.

Accessibility. Inventory will need to be stored in a way that’s easy to receive and put away when new, then pick, pack and ship out to customers later on.

In order to do this, there are several things to think about:

1) Warehouse layout

Your warehouse will need to balance having enough storage space for inventory, while providing enough working space for staff to move around and complete tasks.

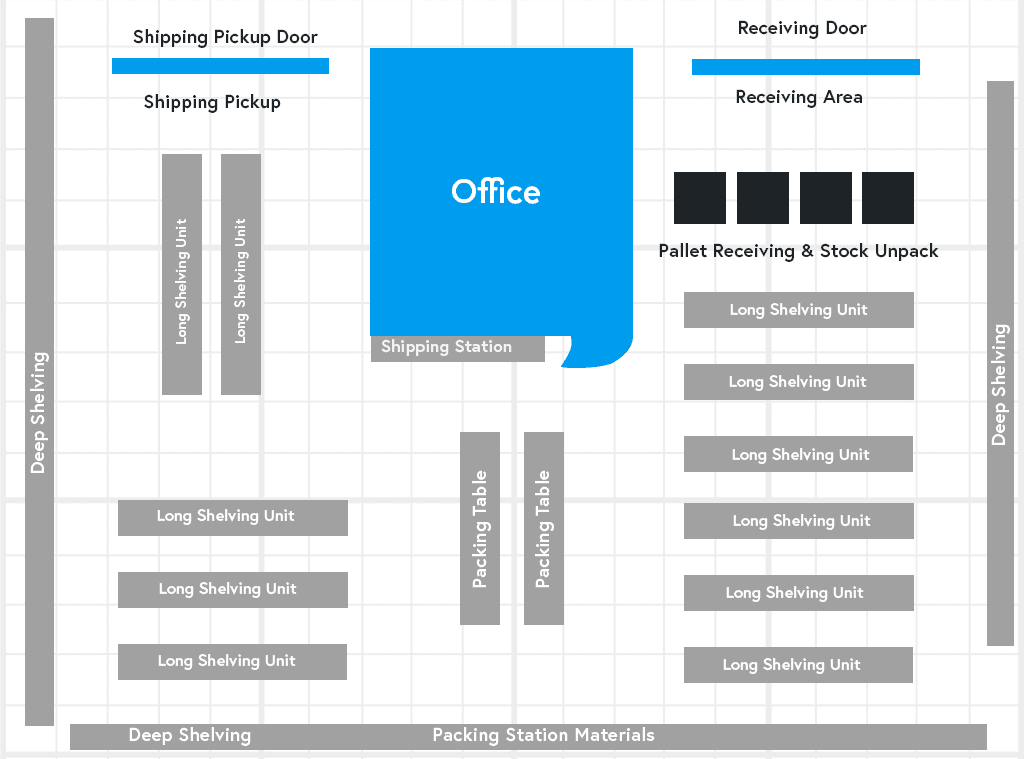

Exact requirements will depend on each individual business, but the following areas tend to be needed in a warehouse layout:

Delivery/receiving area.

Unpacking and book-in area.

Warehouse office.

Main storage area.

Area for excess, obsolete or dead stock.

Packing table(s).

Shipping station(s).

This can be tricky – especially when dealing with a limited space. So it’s best to sketch out your warehouse layout to scale before setting it up or changing what you already have:

Space and manoeuvrability is a key thing to remember.

Pickers need to be able to walk up and down aisles without getting in each other’s way. And should also have enough room to actually pick items.

2) Warehouse labelling

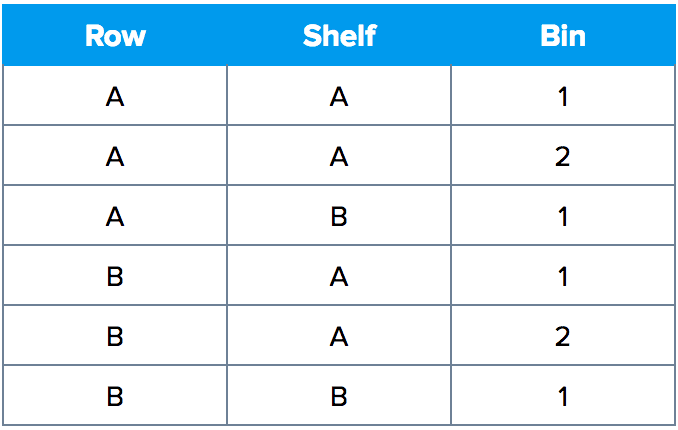

Specific locations and clear labelling are essentials for effective inventory storage. Your team should be able to look at your inventory system and see exactly where any product is located.

Practicality is king here.

Stick with simple alphanumeric combinations labelling specific rows, shelves and then exact bin locations:

So you always know, for example, that all your blue t-shirts sized medium will be in Row A – Shelf B – Bin 1. And the pattern can be continued like this.

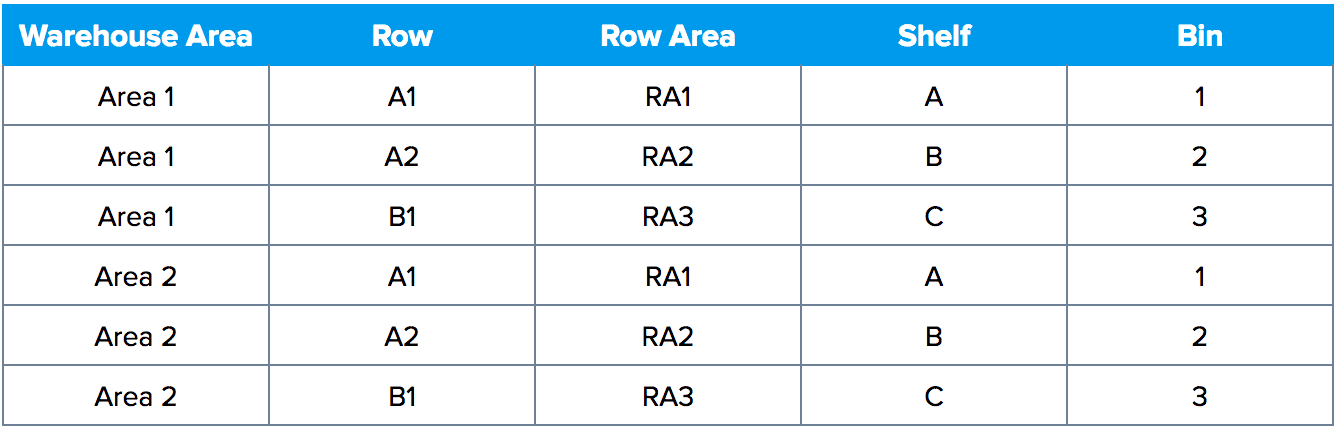

Larger warehouses can extrapolate forward as much as needed with the same concept:

The bigger your facility, the more in-depth you’ll need to go with your location labelling to achieve optimal inventory storage.

3) Arranging inventory

Another key part of inventory storage is determining the exact location each product should be stored within your warehouse.

Ideally, sales volume should be taken into account for this.

Veeqo research found that 60% of a company’s sales tend to come from just 20% of their products. Meaning you can severely reduce picker walking time by:

Identifying that 20% of products from past sales data in your business;

and then storing these as close to the packing desk as possible.

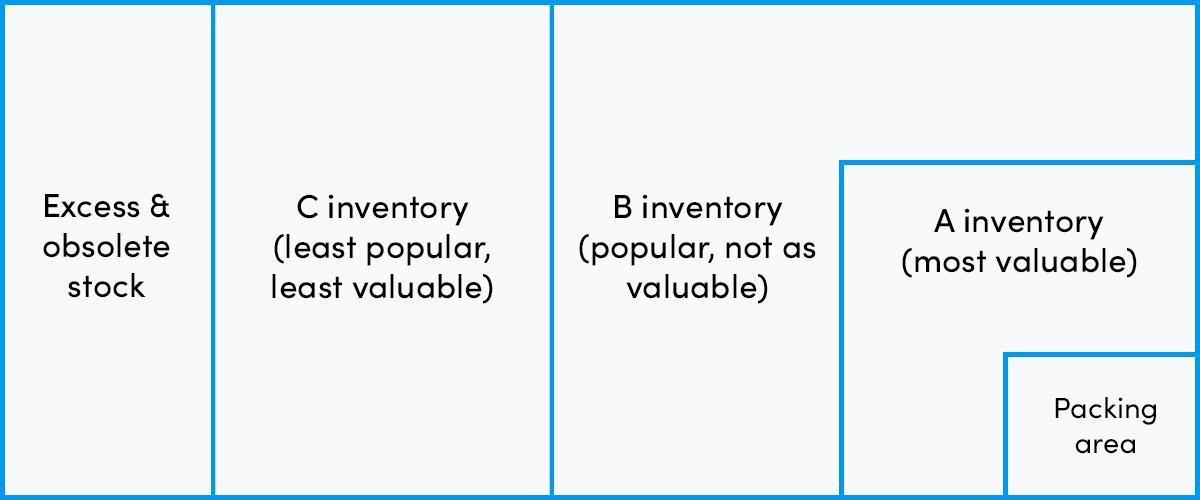

ABC Analysis is an inventory management technique that can become very useful here. This divides all on-hand inventory into three groups – A, B and C:

A Items: Are of high value and bring in most of profits.

B Items: Are sold often, but less valuable/profitable than A items.

C Items: The rest of your inventory that doesn't sell much and generates the least revenue.

You can then decide that ‘A items’ will be placed closest to the packing desk, while ‘C items’ will be farthest away. Like this:

Some small and lightweight items may even be sold frequently enough to warrant being stored on shelves above the packing desks themselves.

Finally:

You can take this concept another layer deep by also identifying which products are most commonly sold together.

So faster selling products are stored closer to the packing desk and products commonly purchased together are stored close or next to each other. Meaning you’re doubling down on reducing walking time for each picker.

Inventory storage equipment

Storing inventory in the safest and most practical way is almost impossible without investing in some form of equipment.

This can differ heavily depending on the goods in question. Retailers selling refrigerators, for example, may require large locations, forklifts and heavy-duty shelving racks. While selling t-shirts or jewelry can usually be done with simple shelves in a smaller space.

With that being said, here’s a look at some of the general equipment to consider:

Shelving units

Some warehouses can work with simple block stacking of products on top of each other, but most will need some kind of shelving to place products on. The most common ones have metal frames with wooden shelves, are easy to build, yet robust. Access to both sides can also be very useful - one side for putting in, one for taking out.

Bins

Warehouse bins are where your individual product variants go into, particularly for smaller items. Each bin will be labelled and assigned to a specific variant to make it easy to locate in the warehouse.

CCTV

Inventory is a business asset, and should be protected as such. Make sure to get a good Closed Circuit Television (CCTV) system set up with signage to indicate it’s in use in order to deter thieves as much as possible.

A quality barcode scanner will help with booking-in, picking, packing, conducting inventory counts and generally keeping your inventory accurate and aligned with what’s recorded in your inventory management software.

Picking cart

Pickers will need a cart on which to carry all the items that are being picked before returning to the packing station. This is particularly useful if you commonly sell multiple items per order, or when using a batch picking system.

Totes

These will sit on the picking cart and carry items for individual orders during a batch picking route. Totes are usually simple plastic containers and will only ever hold items for one order at a time.

Packing desk

A professional packing desk is very solid, larger than a normal office desk and has rolls so that you can get easy access to your packaging materials. It’s worth having at least two, so someone else can jump in during busy periods.

Packaging materials

This will involve your different sized shipping boxes - we recommend around 3-5 options to strike a balance between speed and shipping costs. Plus, tape and all the protective inner packaging - like bubble wrap, shredded paper or air pillows (determined by how fragile your items are in transit).

Printers

You’ll need a good quality A4 lazer printer for invoices, and a typical 6x4” shipping label printer (Dymo is great for this). For your A4 printer, think about speed of printing the first page, speed of printing multiple pages and cost per page.

Shipping computer

This is a dedicated computer solely for shipping out orders - printing out labels, marking orders as shipped, sending out tracking details and/or using shipping software. It’s best to opt for a touchscreen to remove the need for keyboard and mouse in this fast-paced environment.

Shipping scales

These weigh all packed shipments and send details to your shipping computer via a direct connection. Dymo are, again, a great option for scales.

Of course, retailers need to consider this equipment from the point-of-view of their own business. Selling certain foods may require a refrigerated unit or cold store, while very high value jewelry may need extra security measures.

The key is to use this guide as a blueprint to build upon and mould to your own business.

We’ve now covered how to plan, replenish and store inventory as a retailer. Next, we’ll move on to inventory analysis in order to use the best and most useful metrics for keeping on top of your stock management going forward.