Inventory Management Techniques

In essence, all the inventory management techniques a retailer needs are covered throughout the different chapters of this guide. These span across a number of different areas and tasks within the field of inventory management - forecasting, purchasing, storing, analyzing, etc.

So in this article, we give a summary of key techniques and ideas you can use to control and manage your inventory in the best way possible.

Inventory management techniques

Choose an appropriate fulfillment option.

Take forecasting seriously.

Set reorder points for each product.

Use EOQ for optimal order quantities.

Give each variant a dedicated warehouse bin.

Sell older inventory first.

Prioritize with ABC analysis.

Always track your metrics.

Verify accuracy with regular counts.

Automate as much as possible.

This is a quick run-down of all the inventory management techniques we mention in this article. Let’s explore each one of these further below:

1) Choose an appropriate fulfillment option

As a retailer, the whole point of having inventory is to sell it. And with ecommerce, this usually means having to store and ship it somewhere too.

So deciding exactly how this fulfillment process will be done is one of the most crucial inventory management techniques to get right.

Your general options are:

Dropshipping: This is where you never see or hold inventory yourself. Instead, it is purchased as each sales order comes in, and shipped directly to the customer.

Third-party logistics (3PL): This is where you would purchase inventory in bulk, but have it sent to a 3PL service. They would then manage inventory and ship orders to your customers for a monthly fee.

Self-fulfillment: This involves setting up your own facility and team. You’d be totally responsible for controlling, managing and shipping inventory.

Each of these options has its own benefits and drawbacks, with the best one depending entirely on individual business requirements. We discuss this in greater depth in Chapter 5: Inventory Storage of this guide.

2) Take forecasting seriously

It’s tempting to skimp out on forecasting inventory requirements. Instead, many retailers will simply guess, or just buy inventory and hope they sell it.

The problem?

This leaves you extremely susceptible to ending up with way too much (or too little) stock on-hand at any one time. And the extra carrying costs involved will be eating into profits every single day.

Make sure to use your past sales data in two ways:

Short term. Look at sales over the past 30-90 days to indicate your short term sales trends and demand for the inventory you hold.

Long term. Look at what sales were like at particular points in the year to indicate where sales tend to spike and dip.

We discuss this in greater depth in Chapter 3: Inventory Forecasting of this guide.

3) Set reorder points for each product

Reordering your products needs to be done in a timely manner.

Leave it too long and you’ll run out of stock. Go too early and you’ll pile up way more inventory than you need.

This is why each product (and ideally each product variant) should have its own reorder point, taking into account:

Safety stock. So you don’t eat into this emergency, backup stock unnecessarily.

Lead time. So you can still cover sales demand while new products get shipped to your warehouse.

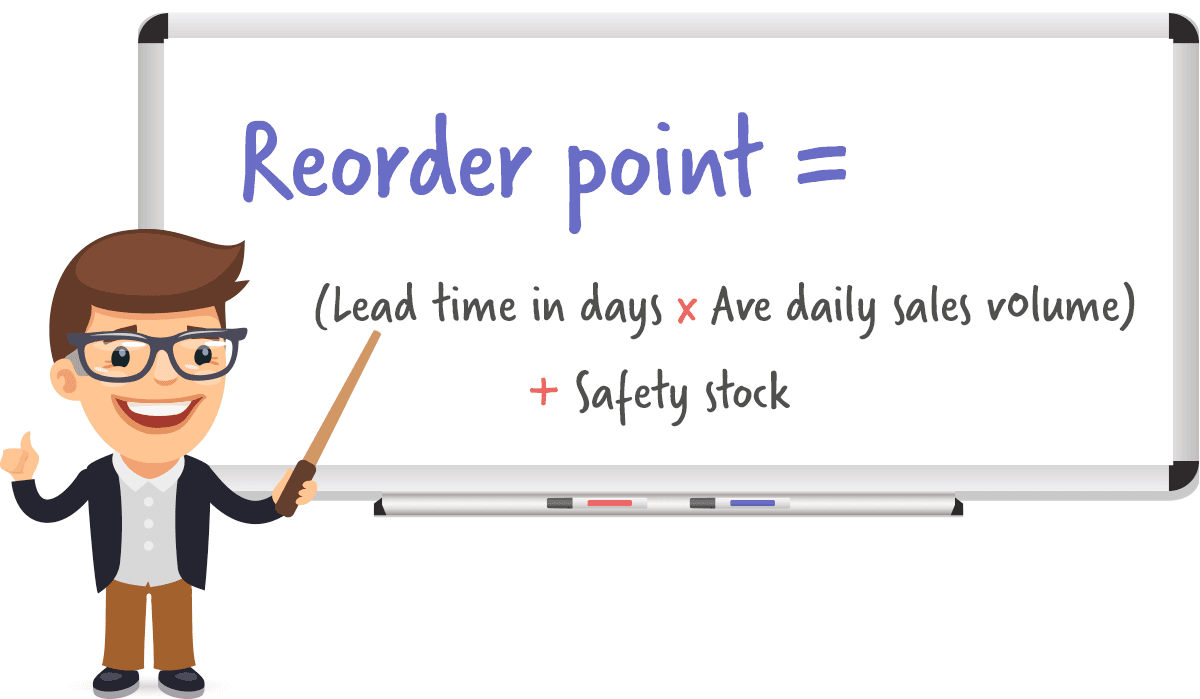

Here’s the formula to work out exact reorder points:

Apply this to each product in your inventory. As soon as a product hits this level, it’s time to place a new purchase order with suppliers.

4) Use EOQ for optimal order quantities

It’s not enough to know when to place a new purchase order. You need to work out exactly how much stock to order at once to keep carrying costs to a minimum.

And economic order quantity (EOQ) is one of the best inventory management techniques to help here.

This is a calculation that helps determine the best amount of inventory to order each time. Helping strike a balance between minimal ordering and carrying costs, while still satisfying demand.

The three variables involved are:

Demand: The number of units sold over a given time period (usually a year).

Relevant ordering cost: Total ordering cost per purchase order. This includes all staff, transportation and any other costs associated with making each purchase order - but not the actual cost of the order itself.

Relevant carrying cost: Assume the item is in stock for the entire time period in question and decipher the carrying cost per unit.

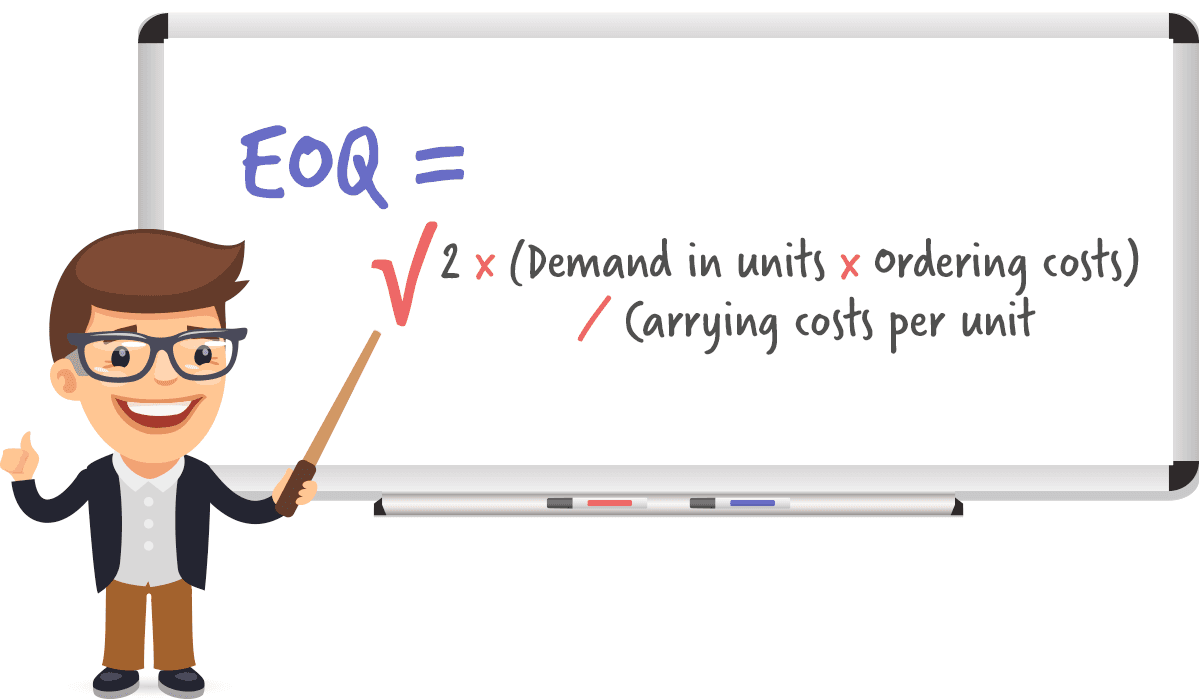

You’ll then put this into the following equation:

We cover reorder points and EOQ further in Chapter 4: Purchasing Inventory of this guide.

5) Give each variant a dedicated warehouse bin

Organizing and arranging items in the warehouse is a key part of good inventory management. Your team should be able to look at your system and easily see where any product is located.

This means creating bin locations with clear labels for each product variant.

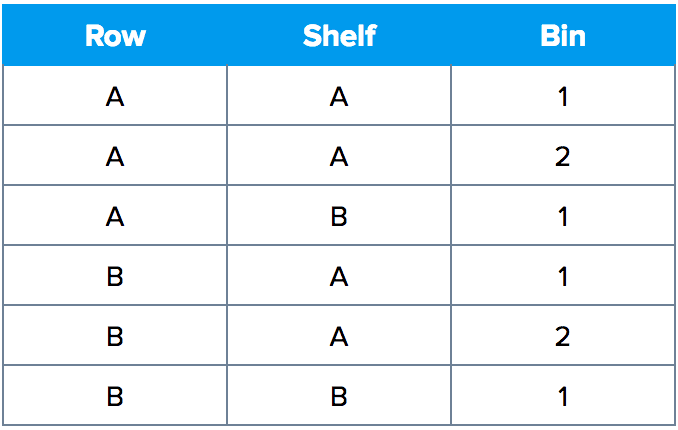

It’s best to avoid fancy names – simplicity and ease of understanding is king here. Numbers and letters are therefore the best route to go.

Start by labelling each row, shelf, then bin location:

So you always know, for example, that all your blue t-shirts sized medium will be in Row A – Shelf B – Bin 1. And the pattern can be continued like this.

We discuss this in greater depth in Chapter 5: Inventory Storage of this guide.

6) Sell older inventory first

For most retailers, the last thing you want is to be always using the newest stock to fulfill orders. This leaves older inventory sitting in the warehouse and susceptible to damage, decay or passing best before dates.

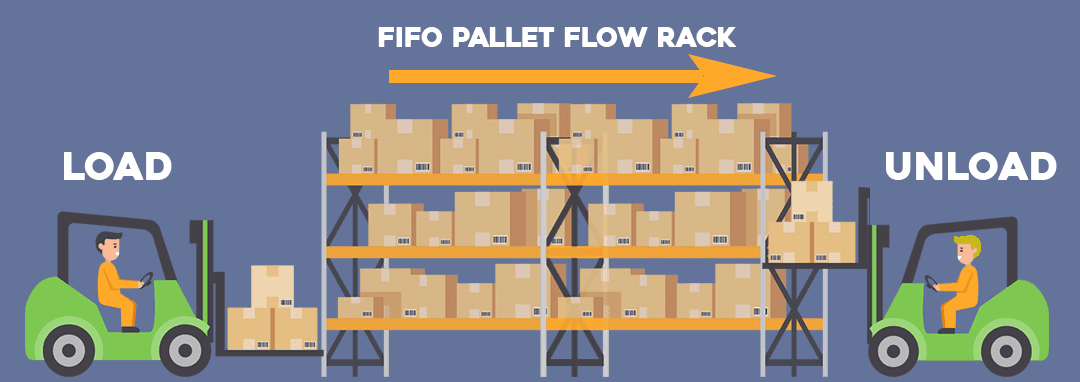

So it’s worth making a rule to store new inventory from the back of shelves and then take from the front - automatically enforcing a first-in-first-out (FIFO) system:

However:

It’s always worth discussing this with your accountant too as they may use a different inventory valuation method for your end-of-year accounts.

7) Prioritize with ABC analysis

ABC analysis is a very common inventory management technique that helps to identify your most valuable inventory.

This means retailers can prioritize inventory better. Allowing them to place greater focus on the particular items and products that bring in the most revenue.

The whole process is about sorting inventory into three buckets:

A inventory

Inventory with the highest value – typically your 20% that brings in 80% of sales/profits. These are usually items with the best profit margins and/or most sales revenue.

B inventory

Inventory that sells regularly, but doesn’t have quite as much value as A – often due to having slimmer margins or higher carrying costs.

C inventory

The remainder of inventory that doesn’t sell as much as A or B, generates the least revenue and is generally least valuable.

It might not make sense to prioritize like this at first. Surely all inventory is important - otherwise you wouldn’t have it, right?

But in reality, some products will sell much better than others. And these are the ones to focus on most to ensure they are readily available and never stock-out.

8) Always track your metrics

Tracking simple metrics and KPIs is one of the inventory management techniques that often gets lost amongst other fancy ideas. But it can still be one of the most powerful.

It’s essential to regularly track at least the following metrics:

Inventory turnover

Measures how many times your inventory is sold over a given time period, giving a critical insight into overall inventory management performance.

Inventory write-off

A measure of any unsold inventory that has become defunct or no longer has any value for the business over a given period.

Gross margin return on investment (GMROI)

Measures the profitability of your inventory over a certain period, giving the gross profit made for every dollar of inventory that’s purchased.

Sell through rate

Takes the amount of inventory a retailer receives, and compares it against what is actually sold over a given period.

Days of inventory outstanding (DOI)

Measures how many days it typically takes to create or buy inventory and turn it into a sale.

Back order rate

Shows the percentage of your total orders over a given period that ended up being placed on back order.

We discuss ABC analysis and these metrics (including the actual calculations needed) in greater detail in Chapter 6: Inventory Analysis.

9) Verify accuracy with regular counts

Unfortunately, errors are inevitable when it comes to your stock. Even with all the inventory management techniques and automations mentioned in this chapter.

So taking a physical count of inventory with regular stock takes is critical.

The traditional way of doing this is to shut the warehouse down for a night (or longer) and complete a big count once or twice a year. But this can be an extremely time-consuming and complex task, especially for large inventories or facilities.

Instead, try spreading it out through the year:

Cycle counting: This is where team members would be given ‘counting tasks’ of a small number of items to do each week. Over the year, each product has then usually been counted and verified several times.

Spot checking: This isn’t done with any specific regularity. It can simply be done if a product is proving particularly problematic or if a team member finds they have some spare time and needs something to do.

Good inventory systems will manage this for you. Assigning regular counting tasks to your team and allowing for easy corrections via digital barcode scanners.

10) Automate as much as possible

Inventory management is a complex job. And it becomes even more complex the more you grow and the more products that get added into your catalogue.

So taking advantage of automation can be possibly the most important inventory management technique out there.

This means utilizing quality inventory management software to do most of the heavy lifting for you. Helping take care of tasks like:

Tracking: So you can sync inventory in real-time across multiple channels without overselling and back orders.

Forecasting: To remove the guesswork and never have too much or too little inventory on-hand.

Purchasing: So you can handle all suppliers and create and manage POs in one place.

Counts: To keep inventory numbers accurate by automatically assigning weekly cycle counting tasks to your team.

Organization: Recording exact bin locations for variants so you can find and pick inventory quickly and accurately.

Quality systems like Veeqo will also let you create automation rules, handle orders and shipping, run reports and push data to accounting software - all in one platform.

Hopefully, this article has provided you with a solid summary of inventory management techniques to utilize in your retail operation. The next chapter will go into detail on efficient multichannel inventory tracking, and how to perpetually keep an accurate live inventory figure.